UKs Leading Soundproofing Supplier

Acoustic & Sound Insulation Slabs

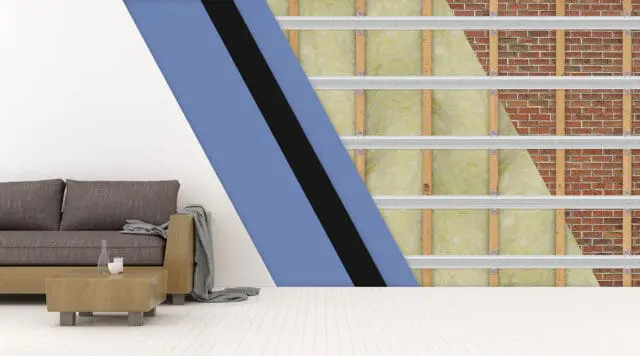

Acoustic sound insulation slabs for soundproofing walls, floors and ceilings. Enhance the sound insulation performance of your soundproof solution with acoustic insulation inside empty cavities

View All ProductsAcoustic Insulation Slabs

Acoustic insulation products FAQs

They are dense, mineral-based materials that reduce sound transmission through walls, floors, and ceilings. They are made from rock wool or glass wool, both of which offer excellent sound-absorbing properties.

The insulation slabs work by absorbing sound waves and reducing the amount of airborne and impact noise that passes through a structure. They are particularly effective at dampening mid to high-frequency sounds. Their density and fibrous nature trap sound energy, converting it into small amounts of heat.

They are most commonly installed inside stud walls, cavity walls, floors, ceilings, and between floor joists. They can also be used when noise reduction is needed, such as around ducts or pipes.

The slabs reduce airborne noise, such as voices, music, and traffic. They also reduce impact noise, such as footsteps, but combining them with resilient layers or underlays is recommended for maximum impact noise reduction.

Sound insulation slabs are specifically designed to reduce sound, whereas thermal insulation slabs focus on retaining heat. While some products can offer both benefits, acoustic insulation tends to be denser and more effective at sound absorption.

Most sound insulation slabs from mineral wool (rock or glass wool) are naturally fire-resistant. This adds an extra layer of safety, especially in buildings that require fire-rated walls or partitions.

No soundproofing solution can block 100% of noise. However, they will significantly reduce noise transmission. Combining them with other soundproofing elements (such as soundproof panels, sound isolation clips and resilient channels) can reduce noise more effectively.

The effectiveness of the sound slabs depends on their thickness and density. Standard thicknesses range from 25mm up to 100mm. Filling a cavity with acoustic insulation is unnecessary; timber joist floors typically require 100mm of insulation. When insulating stud walls, do not overfill the area. For example, a 3×2 stud would only require 50mm of insulation.

Insulation slabs vary in density from 45kg/m3 to 140kg/m3. The optimum density is between 60 and 80kg/m3. When comparing sound insulation slabs on their own, the higher-density slabs offer minimal soundproofing gains.

Yes, for optimal soundproofing, it is often recommended to combine acoustic insulation slabs with other materials like soundproof plasterboard, resilient bars, decoupling isolation clips, and acoustic sealants. These work together to block, absorb, and isolate sound.

Yes, many people install sound insulation slabs themselves, especially in stud walls or floor joists. However, it’s essential to follow manufacturer guidelines to ensure proper installation.

Many insulation slabs are made from recycled materials, such as recycled glass, and are recyclable. Mineral wool products are also generally considered environmentally friendly.

Popular soundproofing categories

Got a question?

Send us a message, and we’ll respond as soon as possible. Alternatively, call 01423 339163 to speak with an adviser.