What are the Best Soundproof Underlays?

Best soundproof flooring underlays: Everything you need to know

In this guide, we will look at soundproof underlays, how they work, and which is best for soundproofing your floors. Whether you are looking to stop the sound of a small child running across the floor or meet Part E regulations, soundproofing underlays play a big part in sound-insulating floors. At Noisestop Systems, we are often asked whether soundproof underlays will soundproof floors against airborne and impact sounds, and the answer is yes. The best soundproofing underlay mats incorporate mass for airborne soundproofing and closed-cell foam to reduce impact noise. In this article, we will take a look at the most effective acoustic underlays and how they will help soundproof your floors.

What’s the difference between airborne and impact noise

Before we get into the underlays, we thought it would help explain the difference between airborne and impact noise.

Airborne noise: Sound that transmits through the air is classed as airborne noise. Common types of airborne noise include conversation, TVs and music.

Impact noise: Caused when an object strikes the floor, and vibrations are transmitted into the room below. Common sources of impact noise include footfall, moving across the floor, and dropping an object.

What is the best way to soundproof a floor?

The best way to insulate floors for sound is to follow these soundproofing principles.

- Add mass to the floor to block airborne sound. Materials with high mass reduce airborne sounds, such as TV noise and talking.

- Improve the floor’s sound absorption. Sound absorption is key to reducing impact noises such as footfall.

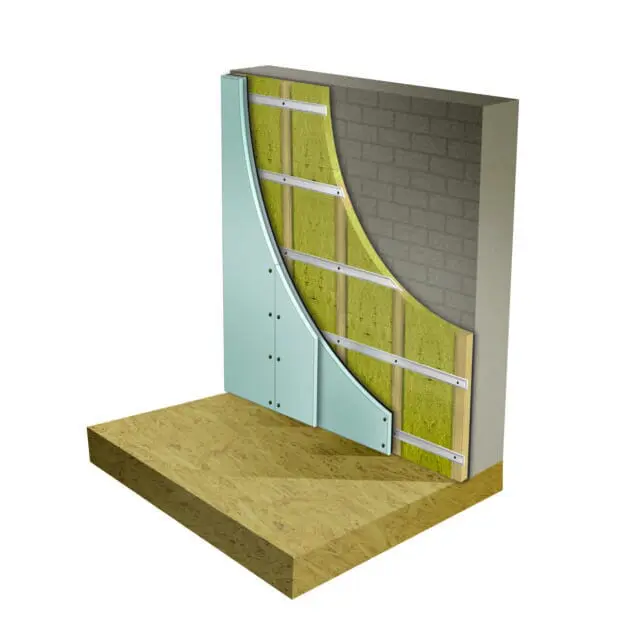

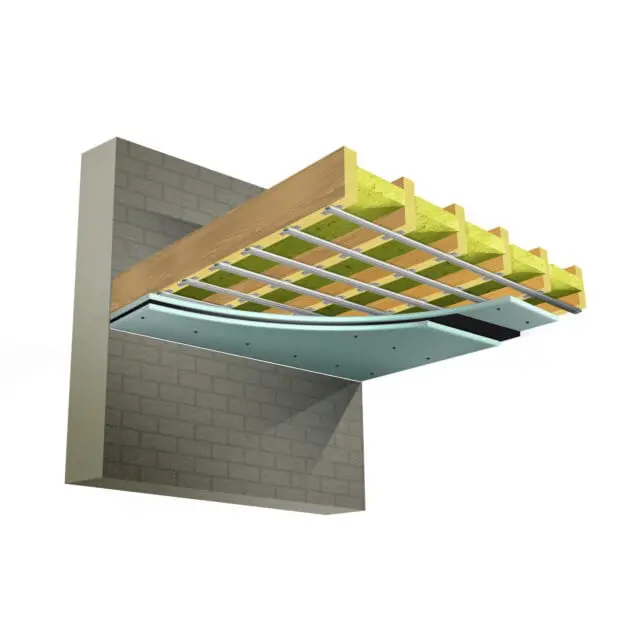

- Soundproofing floors with timber joists can benefit from additional acoustic insulation in the floor cavity, which adds mass and improves sound absorption.

- As with most soundproofing solutions, floors benefit from a combination of materials that offer the best sound insulation rather than a stand-alone solution.

If you are considering insulating floor joists to reduce sound, we offer a range of acoustic insulation for soundproofing floors. As a rule, we recommend using 100mm thick slabs, as this fills a good portion of the cavity. The other factor to consider is the density of the insulation; we recommend using 60kg/m3 slabs, as these offer the best level of soundproofing without paying more for diminishing returns acoustically. You will pay more for higher-density slabs, but you won’t see a return on your soundproofing.

Best soundproof flooring underlays

There are various soundproof underlays available. Here are some of the best soundproofing underlay options.

How do acoustic underlays soundproof floors

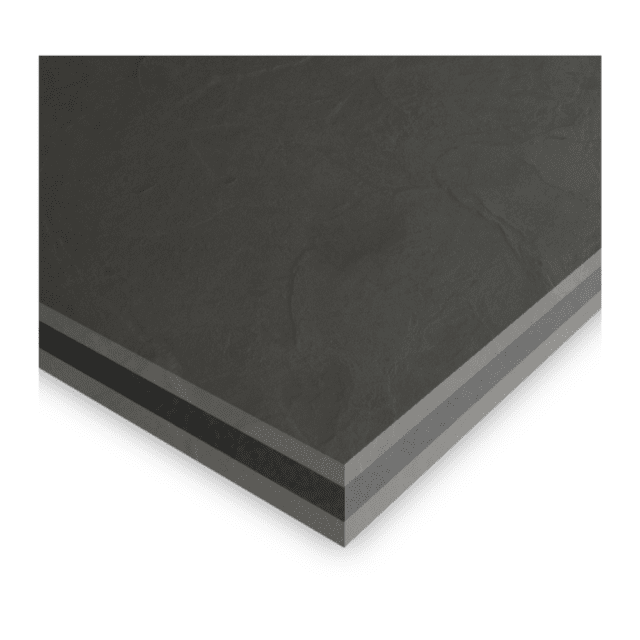

Soundproof underlays are manufactured with multiple layers; these different layers block and absorb impact and airborne sounds. An acoustic underlay will combine acoustic-grade closed-cell foam for absorbing impact and vibration, and layers of mass-loaded vinyl to add the density required to reduce airborne sound.

How does a soundproof underlay block airborne sounds?

The material that soundproof underlays use to block airborne sounds is mass-loaded vinyl. Mass-loaded vinyl is a high-density soundproof membrane used to reduce airborne sound in acoustic underlays and as a stand-alone floor soundproofing product. Vinyls are widely used in soundproofing for underlays and soundproof boards due to their high mass per square meter, with an impressive 10kg/m² in a 4-5mm thick sheet.

Barrier Shield mass-loaded vinyl sheet 10kg/m²

Mass = resistance to airborne sound

Airborne sound (voices, TV, music) moves air molecules. For a material to pass through another material, the first material has to move with the air pressure changes.

MLV is:

-

Very dense for its thickness

-

Much heavier than foam, rubber, or cork

More mass means:

-

More force is required to make it vibrate

-

Less sound energy gets transmitted through

Limp, not rigid (this is key)

MLV is flexible, not stiff. That matters because:

-

Rigid materials have resonant frequencies that pass sound easily

-

Limp materials don’t “ring” or amplify vibration

Because MLV bends without springing back:

-

Sound energy isn’t efficiently re-radiated on the other side

-

Transmission loss stays consistent across mid–high frequencies

Airtight barrier

Airborne sound loves gaps.

Mass-loaded vinyl MLV:

-

It is continuous and non-porous

-

Seals tiny air paths that foam or felt can’t

Once the air can’t move, sound transmission drops dramatically.

How do acoustic underlays block impact sound?

Acoustic underlays that block impact sounds have a layer of acoustic-grade closed-cell foam. These foams absorb impact sounds created by footfall and movement across the floor.

- Mass-loaded vinyl to reduce airborne noise

- Acoustic closed-cell foam to absorb impact noise

- Mass-loaded vinyl to reduce airborne noise

Closed-cell foams are ideal for absorbing impact and vibration noise:

Impact absorption (footsteps, dropped objects)

Closed-cell foam is made of millions of tiny sealed air pockets. When something hits it:

-

The cells compress and rebound, spreading the force over time

-

That reduces the peak impact energy transmitted into the structure below

-

Less energy = quieter “thud”

Think of it like a shock absorber rather than a sponge.

Vibration damping

Structure-borne noise (footfall, machinery, bass) travels through solid materials as vibration. Closed-cell foam helps because:

-

It has viscoelastic behaviour, part elastic, part energy-dissipating

-

As it deforms, some vibration energy is converted into low-grade heat

-

This breaks up vibration paths before they reach the floor or ceiling below

This is why it’s especially effective under hard floors (laminate, vinyl, engineered wood).

Resilience = long-term performance

Closed-cell foams:

-

Don’t permanently collapse under load

-

Maintain thickness and stiffness over time

-

Keep their acoustic performance even after years of compression

Open-cell foams often flatten, reducing impact isolation.

Moisture resistance (bonus but essential)

Because the cells are sealed:

-

Moisture doesn’t soak in

-

No swelling or degradation

-

Stable acoustic behaviour over time

This matters a lot in floors, where humidity changes are constant.

The best soundproofing underlay

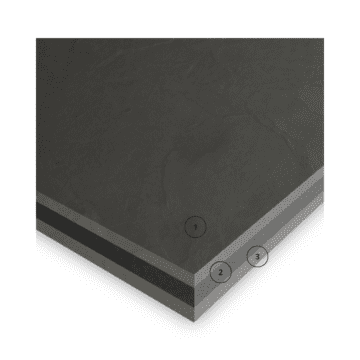

The best soundproof underlay has to offer the most overall soundproof insulation, and that’s the Noisestop F7 Plus. Reducing both impact and airborne noise due to its triple-layered configuration of two layers of the mass-loaded vinyl sandwiching the closed-cell acoustic foam.

Noisestop F7 Plus

The acoustic closed-cell foam and the two layers of mass-loaded vinyl incorporated into the Noisestop F7 Plus work together perfectly to improve the sound insulation of any floor.

- Reduce airborne and impact noise

- Triple-layered for added protection against airborne sound

- Quick and easy DIY install

- Suitable for use over concrete and wooden floors

- Ideal for carpeted floors and most domestic floor finishes

Some floor finishes would require our 9mm interlocking MDF overlay board.

Offering the best overall sound insulation means using this underlay without needing acoustic insulation. However, incorporating sound insulation inside wooden floors will significantly reduce sound transmission between them.

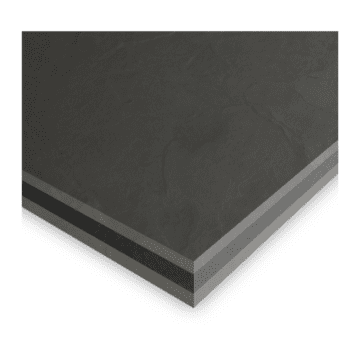

Best acoustic underlay to reduce impact noise

The best acoustic underlay for reducing impact sound is the 12mm Noisestop Acoustic Underlay. We have chosen this underlay as the best for impact sound, as it has performance levels similar to those of the thicker 15mm underlay. The single layer of vinyl and the closed-cell foam offer a good balance of sound insulation.

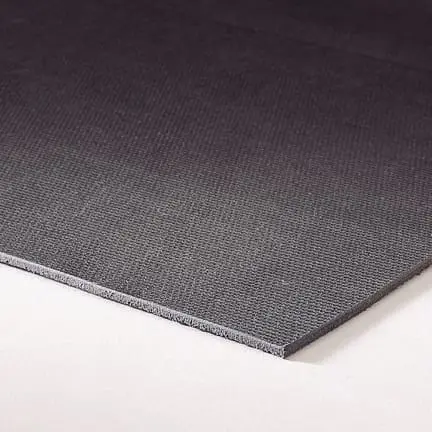

Noisestop Acoustic Underlay

The acoustic closed-cell foam and the mass-loaded vinyl layer incorporated into the Noisestop Acoustic Underlay work together to improve impact sound insulation for any floor.

- Reduces impact noise

- Double-layered to reduce impact sound

- Quick and easy DIY install

- Suitable for use over concrete and wooden floors

- Ideal for carpeted floors and most domestic floor finishes

Some floor finishes would require our 9mm interlocking MDF overlay board.

Combining the Noisestop Acoustic Underlay with acoustic insulation between floor joists will significantly improve the sound insulation of wooden flooring.

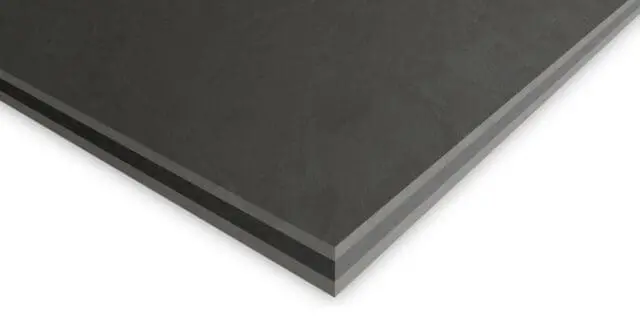

Best soundproofing underlay for reducing airborne noise

Our choice of the best material to soundproof a floor against airborne noise is one of our thinner solutions. The Noisestop Barrier Shield 10kg/m2 mats are our pick for soundproofing floors against airborne noise.

10kg Barrier Shield

We chose Barrier Shield because it is the same material used in all the other acoustic underlays. A Barrier Shield is a sheet of mass-loaded vinyl. As we mentioned earlier, the vinyl part of an acoustic underlay blocks airborne sound.

- Reduce airborne noise

- DIY friendly installation

- Cost-effective

This must be considered if you are looking for an option to insulate your floor against airborne noise. The Barrier Shield will not reduce impact sound transfer on its own; however, combined with our impact mat, you will soundproof your floor against impact and airborne noise.

Best soundproof underlay for floors with carpets

Either of our two main soundproof underlays, Noisestop F7 Plus and Noisestop Acoustic Underlay, can be fitted without the need for traditional carpet underlay.

An acoustic underlay will give the same feeling underfoot as a regular underlay while absorbing impacts through the floor. Standard carpet underlays are made from a much lower-grade open-cell foam, which lacks the strength and stability of closed-cell foam, which is why they don’t stop impact noise.

Best soundproofing option for laminate and engineered floors

All the acoustic underlays we provide work well below laminate and engineered floors. We have chosen the Noisestop Impact mat because it is the most suitable for this floor type. This floor type generates higher levels of impact sound than carpet; therefore, we feel the impact mat is best, given its installation method, compared to thicker acoustic underlays. Solid floor finishes are laid directly over the mat, avoiding the need for additional resilient layers required with thicker acoustic underlays.

Noisestop Impact Mat

- Reduce impact noise

- Slim profile

- Easy to install

- Cost-effective

The drawback of thicker underlays is that you would need an additional layer over the soundproofing to stabilise the laminate. The best thing about the Impact Mat is that you can install your chosen floor directly over it.

How to soundproof floors

Soundproofing floors requires adding mass, sound absorption, and decoupling. It follows the same principles as soundproofing walls and ceilings. By improving the floor’s sound absorption, you will soundproof it against airborne and impact noise.

- To block airborne sound, add mass to the floor area. Acoustic insulation slabs and underlays are materials used to add mass to the floor. Soundproof between floor joists to block and absorb noise, acoustic underlays with mass-loaded vinyl add to the floor’s mass.

- Improve the floor’s sound absorption by using acoustic underlays to reduce impact noise and acoustic insulation in empty floor cavities to prevent sound from resonating within the floor joists.

- Use acoustic underlay mats to decouple floors and isolate the structure from the floor finish. Soundproof mats and membranes over the subfloor isolate the floor finish and stop sound from transmitting into the floor and the rooms below.

How to install acoustic underlays

- Ensure the floor on which you are laying the mats is free of dirt and debris, and that any holes have been filled.

- If you use gripper rods or perimeter edge strips, install them before the acoustic underlay.

- Lay the soundproof mats over the floor in a brick-bond pattern if possible.

- The mats should be fitted tightly together with no gaps between them.

- Use the High Tack Tape to secure the joins.

- Lay your floor finish or carpet underlay over the soundproof matting.

Fitting hard floor finishes over acoustic underlay mats

If you plan to use laminate, engineered, or LVT over acoustic underlays, use a resilient layer below the floor finish.

Using an interlocking floor ensures a stable base for your chosen flooring. It is important to note that the floor will be more secure if it interlocks. You will risk movement if you use flooring that doesn’t lock together. Our 9mm T&G interlocking MDF sheets are ideal for laying over acoustic underlays to secure the final floor finish.

Soundproofing products to install acoustic underlays

To fit your soundproof underlays, you might need some of these products.

If you use a carpet underlay with your soundproofing underlay, you will need to raise the height of the carpet gripper rods. Perimeter edge strips fitted below the gripper rods will ensure the gripper rod is at the required height for your carpet.

Secure the underlay mats with High Tack Tape along the edges as they butt together.

Our 9mm interlocking MDF sheets over the acoustic underlay reduce any potential movement in laminate flooring and LVT.

F7 Plus 15mm Soundproof Underlay 1.2m x 1.2m

£41.95 exc VAT.

12mm Soundproof Acoustic Underlay 1.2m x 1.2m

£31.95 exc VAT.

F7 9mm Soundproof Underlay 1.2m x 1.2m

£26.95 exc VAT.

Noisestop Impact Mat 3mm & 5mm

£108.75 exc VAT.

Mass Loaded Vinyl Barrier Shield - 5kg & 10kg 1.2m x 1.2m

£10.05 exc VAT.

Perimeter Edging Gripper Rod Strips 9mm x 1200mm x 25mm

£5.65 exc VAT.

Perimeter Isolation Tape 25m x 100mm x 5mm

£12.3 exc VAT.

High Tack Tape 33m x 50mm

£12.9 exc VAT.