Noisestop Acoustic Underlay 12mm x 1200mm x 1200mm

£31.95 ex. VAT

In stock, ready to ship

Estimated Delivery: 3 - 5 Days

(30th Jul - 1st Aug)

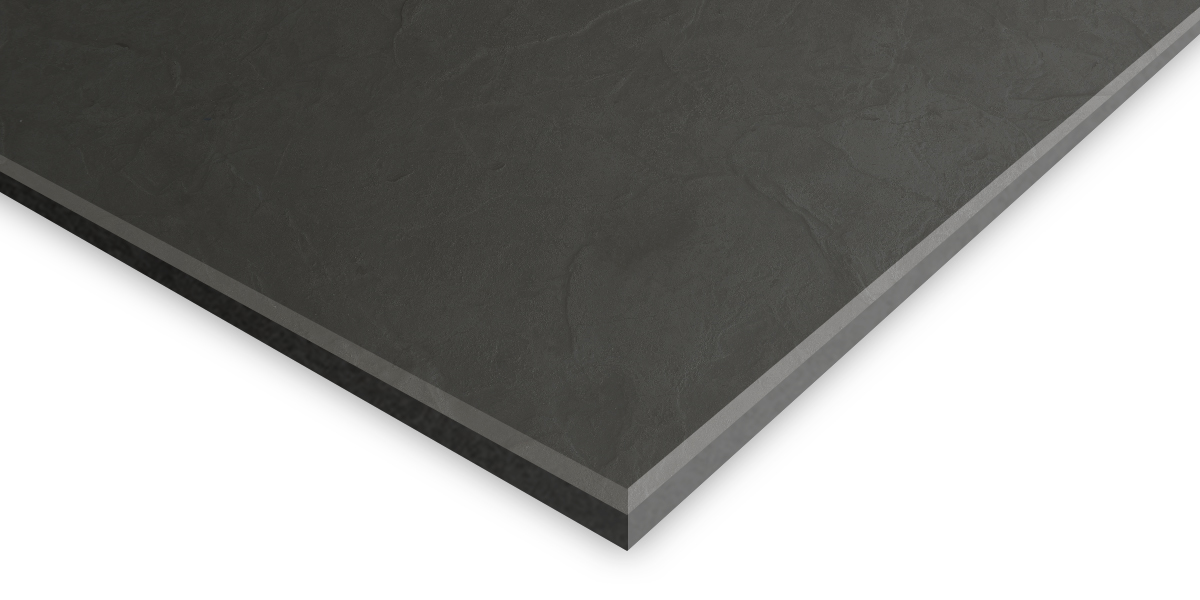

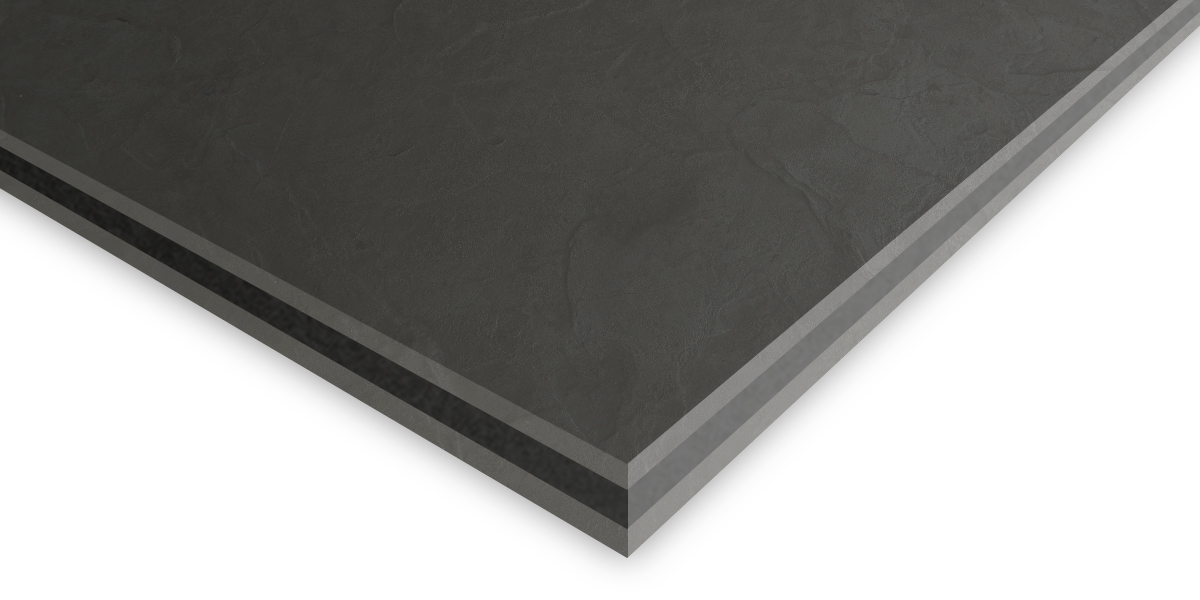

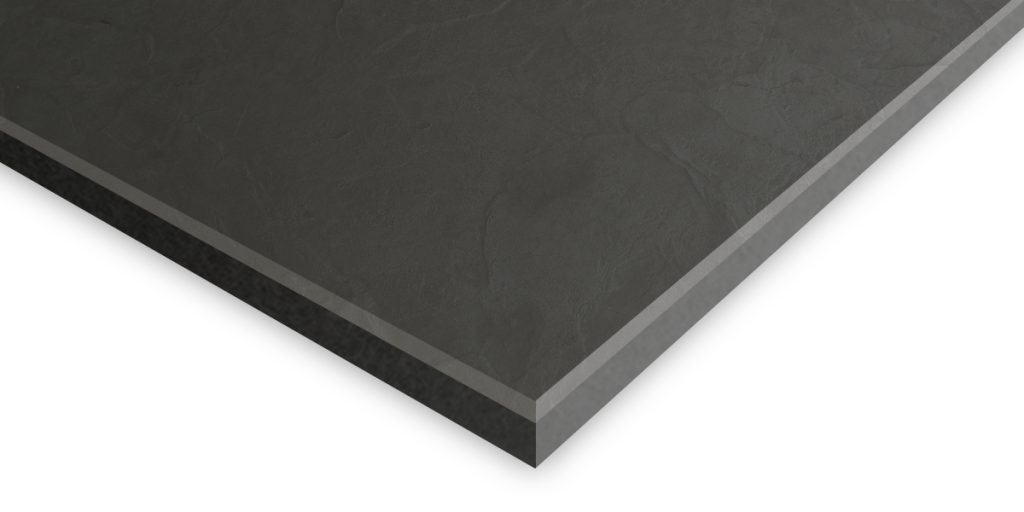

Noisestop Acoustic Underlay 12mm is a heavy-duty overlay mat that provides excellent impact sound reduction against footfall and helps minimise airborne sounds. Only 12mm thick, the soundproof underlay has minimal impact on floor build-up. The product combines acoustic-grade closed-cell foam with mass-loaded vinyl. The mats are easy to install as they are loosely laid over the floor and can be cut to size using a sharp knife.

The dual layer means applying the mats foam side up for carpeted floors and foam side down for hard floor finishes. Noisestop Acoustic Underlay is suitable for use on its own or as part of a complete soundproof floor system compliant with Part E Regulations.

- Mass-loaded vinyl 7.5kg/3mm – High mass barrier layer for sound absorption.

- Closed cell foam 9mm – Acoustic grade foam to dampen and absorb vibration sound.

- System thickness 12mm

- Size 1200mm x 1200mm (1.44sqm)

- Weight 16kg

Thermal Resistance R:

- Closed Cell Foam: 0.23 m² K/W

- Mass-loaded vinyl 0.14 m² K/W

Thermal Conductivity λR:

- Closed Cell Foam: 0.039 W/mK

- Mass-loaded vinyl 0.037 W/mK

Reaction to Fire

- Closed Cell Foam: FMVSS 302

- Mass-loaded vinyl 10kg EN 13501-1 B-s2,d0 (2

The higher the figure for airborne, the better the performance. The lower the figure for impact the better the performance.

Timber floor airborne results

18mm chipboard laid direct to 200mm joist with 10mm plasterboard.

Without soundproofing 41dB

With 12mm Acoustic Underlay 48dB

With 12mm Acoustic Underlay and 100mm insulation 52dB

With 12mm Acoustic Underlay and 100mm insulation with Soundbreaker bars and 12.5mm plasterboard (two layers) 60dB

Timber floor impact results

18mm chipboard laid direct to 200mm joist with 10mm plasterboard.

Without soundproofing 79dB

With 12mm Acoustic Underlay 52dB

With 12mm Acoustic Underlay and 100mm insulation 50dB

With 12mm Acoustic Underlay and 100mm insulation with Soundbreaker bars and 12.5mm plasterboard (two layers) 46dB

Concrete floor impact results

Due to the high mass of concrete flooring, acoustic underlays are only used to reduce impact noise.

200mm Concrete flooring

Without soundproofing 79dB

With 12mm Acoustic Underlay 52dB

Note: Every 10 decibels(dB) reduction in noise level is roughly perceived as a halving of the perceived loudness. So, for instance, if you have a sound that measures 70dB and it decreases to 60dB, it would sound about half as loud to the human ear. Decibels explained.

- Laid directly over the existing sub-floor

- Loose laid no requirement to bond to the floor. Part E requires bonding for new builds and conversions.

- Butt the edges together

- Reduce movement with High Tack Tape along the joins

- Cut to size using a sharp knife or a fine toothsaw

Carpet as the floor finish

Acoustic underlays can be used directly below the carpet. When installing the underlay, you should consider using the perimeter edging strip to ensure the gripper rods are the same height as the carpet. The gripper rods and the perimeter edging should be nailed to the floor using a 30mm nail.

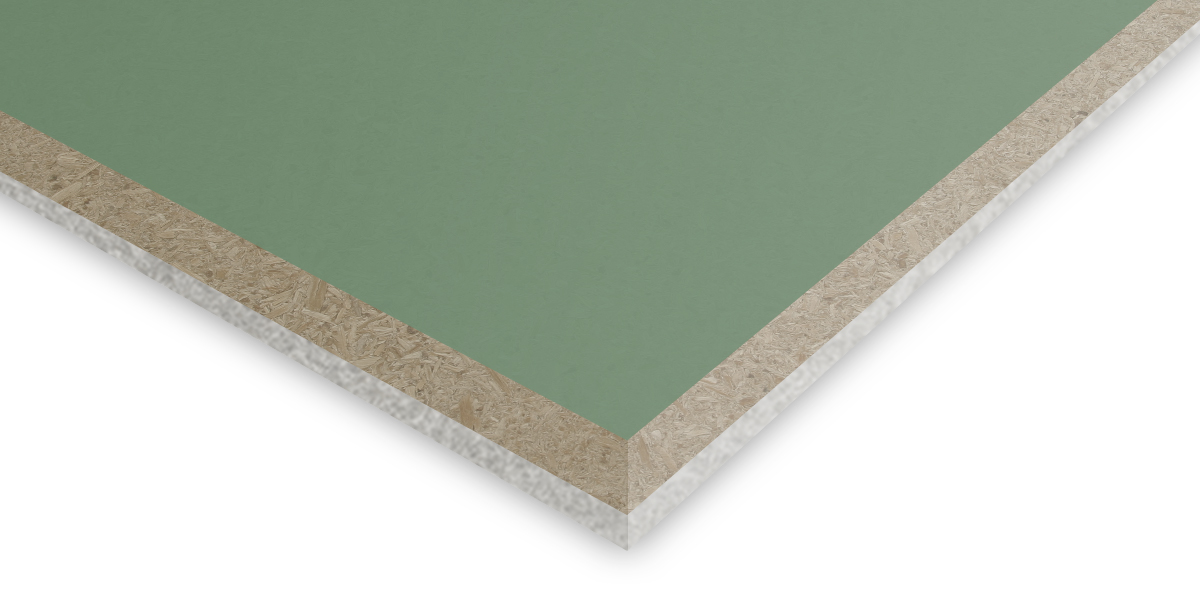

Hard floor finishes equal to or less than 14mm

Hard floor finishes, including laminate, engineered, and tiles, should use a resilient layer between the soundproofing and the floor finish. We recommend a sheet material such as ply or interlocking MDF. The layers are secured using a floor-grade adhesive such as Isobond floor adhesive. To prevent potential flanking sound from transmitting from the floor to the walls, isolate the flooring using isolation tape fixed to the wall.

Hard floor finishes over 14mm

Floor finishes over 15mm can be installed directly on the soundproof mats. Secure the flooring using the Isobond adhesive. Isolate the flooring using isolation tape fixed to the wall to prevent potential flanking sound from transmitting from the floor to the walls.

Due to the nature of most of the materials we supply, orders are typically delivered on pallets.

All orders will be wrapped, protected, and secured to the pallet to ensure they arrive in the best possible condition. Goods will be delivered as near to the property as possible. The drivers will not be able to carry orders into your property.

Deliveries are made between 8am and 6pm, Monday to Friday.

Once an order has been placed, you will be notified of the expected delivery date. Please ensure someone is available to sign for the delivery.

We charge a flat delivery rate of £60 plus VAT for palletised deliveries. We do not charge per pallet, no matter how many pallets are used to deliver your order.

Orders placed for items weighing less than 20kg will be sent via courier for £20 plus VAT.

We have a high stock level, so we typically deliver orders in approximately three working days.

If you want to speak to us regarding your delivery, please call 01423 339163.

Please check out our full delivery terms for more details.

Got a question?

Send us a message, and we’ll respond as soon as possible. Alternatively, call 01423 339163 to speak with an adviser.