Concretedeck Acoustic Flooring 2400mm x 600mm T&G

£38.95 – £44.95 ex. VAT

Estimated Delivery: 3 - 5 Days

(30th Jul - 1st Aug)

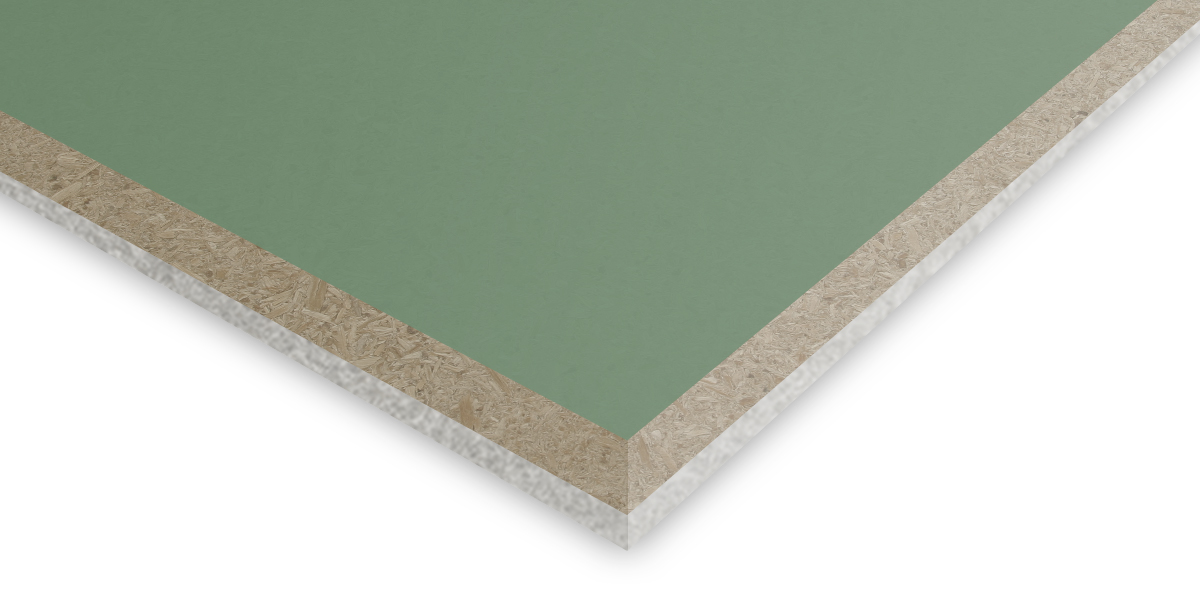

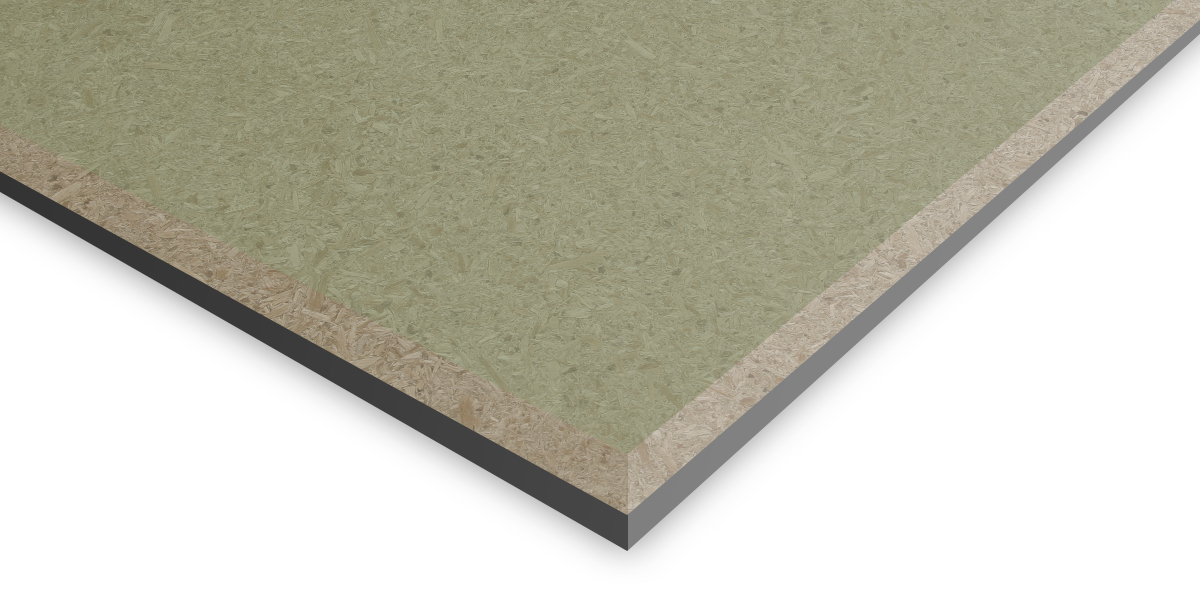

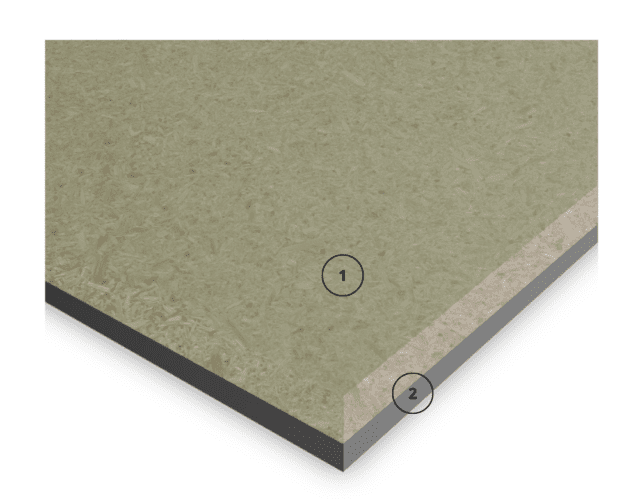

Choose Concretedeck for concrete floor soundproofing to significantly reduce impact sound transmission. Concretedeck 18mm, 23mm, and 27mm consist of a 5.5 mm layer of cross-linked Isopoli bonded to 22mm, 18mm, and 12mm P5 V313 moisture-resistant chipboard.

It enables a concrete floor to meet the sound transmission standards of Approved Document E 2003 and subsequent amendments in 2004, 2010, 2013, and 2015. Concretedcek acoustic flooring is used in new builds and conversion projects to reduce impact sound transfer through concrete subfloors.

This concrete floor soundproofing system does not need the additional protection of a moisture barrier (VCL) vapour control layer because the Isopoli will not absorb the moisture from a virgin screed.

- P5 V313 moisture-resistant chipboard 22mm, 18mm and 12mm

- Layer of cross-linked Isopoli 5.5 mm

Dimensions

- Concretedeck 27 – 2400mm x 600mm x 27mm

- Concretedeck 23 – 2400mm x 600mm x 23mm

- Concretedeck 18 – 2400mm x 600mm x 18mm

Weight

- Concretedeck 27 – 22.8kg per sheet

- Concretedeck 23 – 18.8kg per sheet

- Concretedeck 18 – 13.0kg per sheet

| Product |

DnT,w+ Ctr |

L’nT,w |

| Concretedeck 18 |

51dB |

53dB |

| Concretedeck 23 |

53dB |

53dB |

| Concretedeck 27 |

53dB |

54dB |

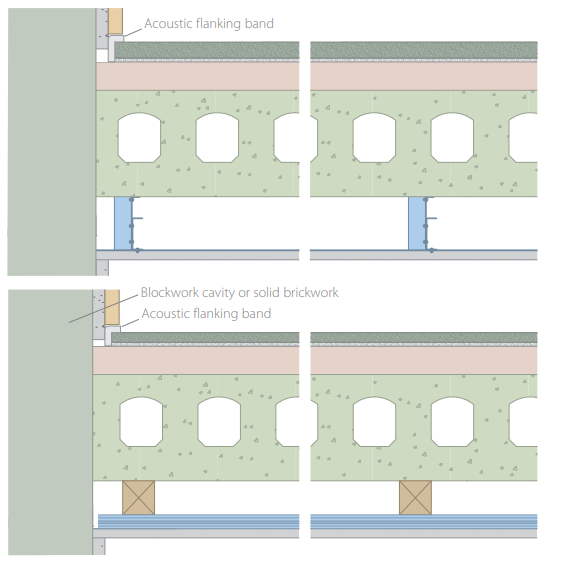

When installed as part of a complete party floor construction, it enables a concrete floor to meet the sound transmission standards of ADE 2003 and subsequent amendments in 2004, 2010, 2013 & 2015

Concretedeck 27mm, 23mm, 18mm

- ≥300kg/m2 hollow core concrete with 80kg/m2 sand/cement screed or 40mm screed

- Min. 75mm void formed by metal frame suspended ceiling system with ≥10kg/m2 plasterboard board ceiling (top) or 50 x 75mm timber battens.

- ≥10kg/m2 plasterboard board ceiling supported on resilient bars @ 400mm centres, perpendicular to the battens min 75mm below the underside of sub-floor.

Lay Concretedeck flooring over dry level screed in brick bond pattern, applying wood adhesive to all tongued and grooved panel joints. Apply a perimeter isolation tape on the edge of the wall just before the boards are pushed against the perimeter walls to isolate the board from the wall. Install skirting and trim off excess perimeter isolation tape.

Stud Partitions

Stud partitioning should be built from the subfloor wherever possible. It is good practice to isolate all partitions built from the sub-floor with Isolation Tape as this will improve the performance of the walls and the floors.

Skirting Boards and Architraves

Reduce flanking sound by isolating skirting boards and architraves from the flooring. Roll the isolation tape over the flooring and place the skirting board on top. Trim excess tape with a sharp knife.

Kitchens and Bathrooms

Install kitchen units onto the structural subfloor. Lay the concretedeck boards up to the legs of the units. Install the plinth to the legs of the units to finish. Use a plywood sheet or similar over the subfloor where floor heights need to be changed for white goods. The flooring should finish at the legs in the bathrooms, and the subfloor should support the bath. You should then install the bath panel to finish. You can use a plywood sheet below the toilet, bath and sink to ensure the floor height throughout.

Due to the nature of most of the materials we supply, orders are typically delivered on pallets.

All orders will be wrapped, protected, and secured to the pallet to ensure they arrive in the best possible condition. Goods will be delivered as near to the property as possible. The drivers will not be able to carry orders into your property.

Deliveries are made between 8am and 6pm, Monday to Friday.

Once an order has been placed, you will be notified of the expected delivery date. Please ensure someone is available to sign for the delivery.

We charge a flat delivery rate of £60 plus VAT for palletised deliveries. We do not charge per pallet, no matter how many pallets are used to deliver your order.

Orders placed for items weighing less than 20kg will be sent via courier for £20 plus VAT.

We have a high stock level, so we typically deliver orders in approximately three working days.

If you want to speak to us regarding your delivery, please call 01423 339163.

Please check out our full delivery terms for more details.

Frequently bought together

Got a question?

Send us a message, and we’ll respond as soon as possible. Alternatively, call 01423 339163 to speak with an adviser.