Noisedeck 18T 2400mm x 600mm x 18mm T&G Flooring

£33.95 ex. VAT

In stock, ready to ship

Estimated Delivery: 2 Days

(29th Jul)

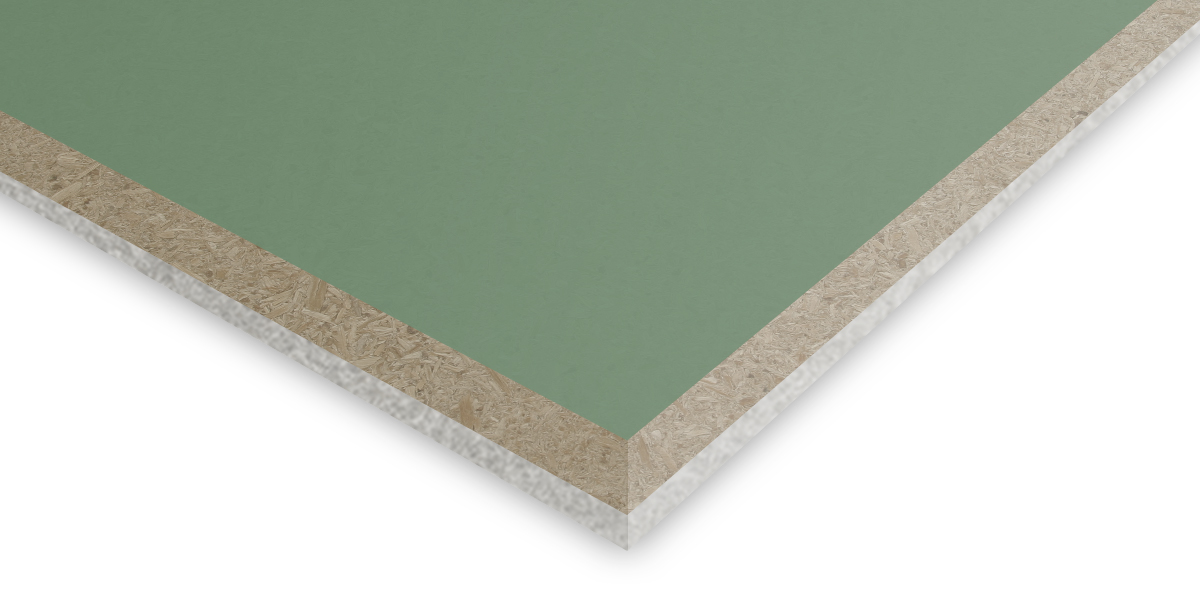

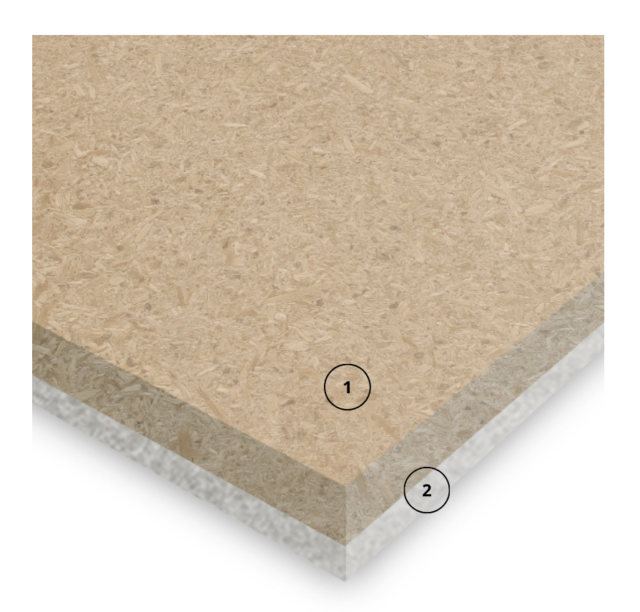

Noisedeck 18T is a slim, high-performing Part E compliant overlay system for timber floor soundproofing. It reduces impact sound transmission. Consisting of a 12mm moisture-resistant chipboard bonded to a layer of 6mm isofiba. At only 18mm thick, this is one of the thinnest Part E compliant systems for timber floors. When installed as part of a separating floor construction, it enables a timber floor to meet the sound transmission regulations of Approved Document E 2003 and subsequent amendments in 2004, 2010, 2013 and 2015.

- Size 2400mm x 600mm x 18mm (1.44m²)

- 12mm moisture-resistant chipboard

- 6mm isofiba

- Weight 13kg

The Noisedeck 18T acoustic floorboard will ensure Part E compliance in new builds and conversions. It can be installed as a complete soundproofing system for separating timber floors. Install the Noisedeck 18T as an overlay system over existing floorboards. Being one of the slimmest soundproof overlay systems at only 18mm means the Noisedeck 18T is a great choice for use in rooms where limits restrict the flooring solution’s depth. When installed as part of a complete sound reduction system, it enables a timber floor to meet the sound transmission regulations of Approved Document E 2003 and subsequent amendments in 2004, 2010, 2013 and 2015.

The Noisedeck 18T comprises the following materials.

- 12mm P5 V313 moisture resistant chipboard

- 6mm layer of Isofiba

- System thickness 18mm interlocking T&G

- Size 2400mm x 600mm x 18mm

- Weight 13kg

Thermal Conductivity:

- 12mm P5 Chipboard: 0.15 W/mK

Thermal Resistance:

- 12mm P5 Chipboard: 0.15 m² K/W

Fire:

- EN13501-1: D-s2, d0

The higher the figure for airborne, the better the performance. The lower the figure for impact, the better the performance.

Overlay system airborne results

Without soundproofing 41dB

With Noisedeck 18T laid over 18mm flooring, 100mm acoustic insulation between joists, Soundbreaker bars and two layers of 12.5mm acoustic plasterboard 48dB

Overlay system impact results

Without soundproofing 79dB

With Noisedeck 18T laid over 18mm flooring, 100mm acoustic insulation between joists, Soundbreaker bars and two layers of 12.5mm acoustic plasterboard 53dB

Note: Every 10 decibels(dB) reduction in noise level is roughly perceived as a halving of the perceived loudness. So, for instance, if you have a sound that measures 70dB and it decreases to 60dB, it would sound about half as loud to the human ear. Decibels Explained.

- Install directly over the existing floor as an overlay system

- Interlocking T&G edges require wood glue to secure them. No mechanical fixing is required

- Lay in a brick bond pattern

- Ensure all joins are supported

- Ensure the flooring is isolated from the walls using the perimeter isolation tapes

Before you start fitting the Noisedeck boards, check the area for debris and nails. Make sure the area is clear before commencing with the installation.

- Fit the isolation tape to the perimeter of the wall.

- Start at the furthest point in the room and lay the first Noisedeck, butting the edge into the isolation tape.

- Apply wood glue along the edges of the boards as you lay them in a brick bond pattern.

- Once the boards have been laid, install the skirting and trim off excess isolation tape.

- Allow 24 hours after completing the installation before commencing any further work on the floor.

We advise that all wall partitions be built before installing the Noisedeck boards.

Kitchens and bathrooms should be fitted onto a suitable platform and not directly onto the Noisedeck boards.

Most floor finishes are suitable for laying directly over Noisedecks. If you are laying tiles, we recommend using suitable flexible adhesive and grout. If additional strengthening is required, sheet materials can be laid over the Noisedecks.

We recommend installing the Noisedeck boards with a suitable ceiling system to meet Part E Regulations. For the highest level of soundproofing, combine with the AcoustiClip Timber Ceiling System.

Due to the nature of most of the materials we supply, orders are typically delivered on pallets.

All orders will be wrapped, protected, and secured to the pallet to ensure they arrive in the best possible condition. Goods will be delivered as near to the property as possible. The drivers will not be able to carry orders into your property.

Deliveries are made between 8am and 6pm, Monday to Friday.

Once an order has been placed, you will be notified of the expected delivery date. Please ensure someone is available to sign for the delivery.

We charge a flat delivery rate of £60 plus VAT for palletised deliveries. We do not charge per pallet, no matter how many pallets are used to deliver your order.

Orders placed for items weighing less than 20kg will be sent via courier for £20 plus VAT.

We have a high stock level, so we typically deliver orders in approximately three working days.

If you want to speak to us regarding your delivery, please call 01423 339163.

Please check out our full delivery terms for more details.

Got a question?

Send us a message and we’ll get back to you as soon as possible. Alternatively, call 01423 339163 to speak with an adviser.