Fitting the AcoustiClip System to Walls

How to fit AcoustiClips to walls

Fitting guide for using the AcoustiClip System – Fitting the AcoustiClip system to walls

This guide will help with fitting the Acousticlip System to walls if you use the following soundproof systems.

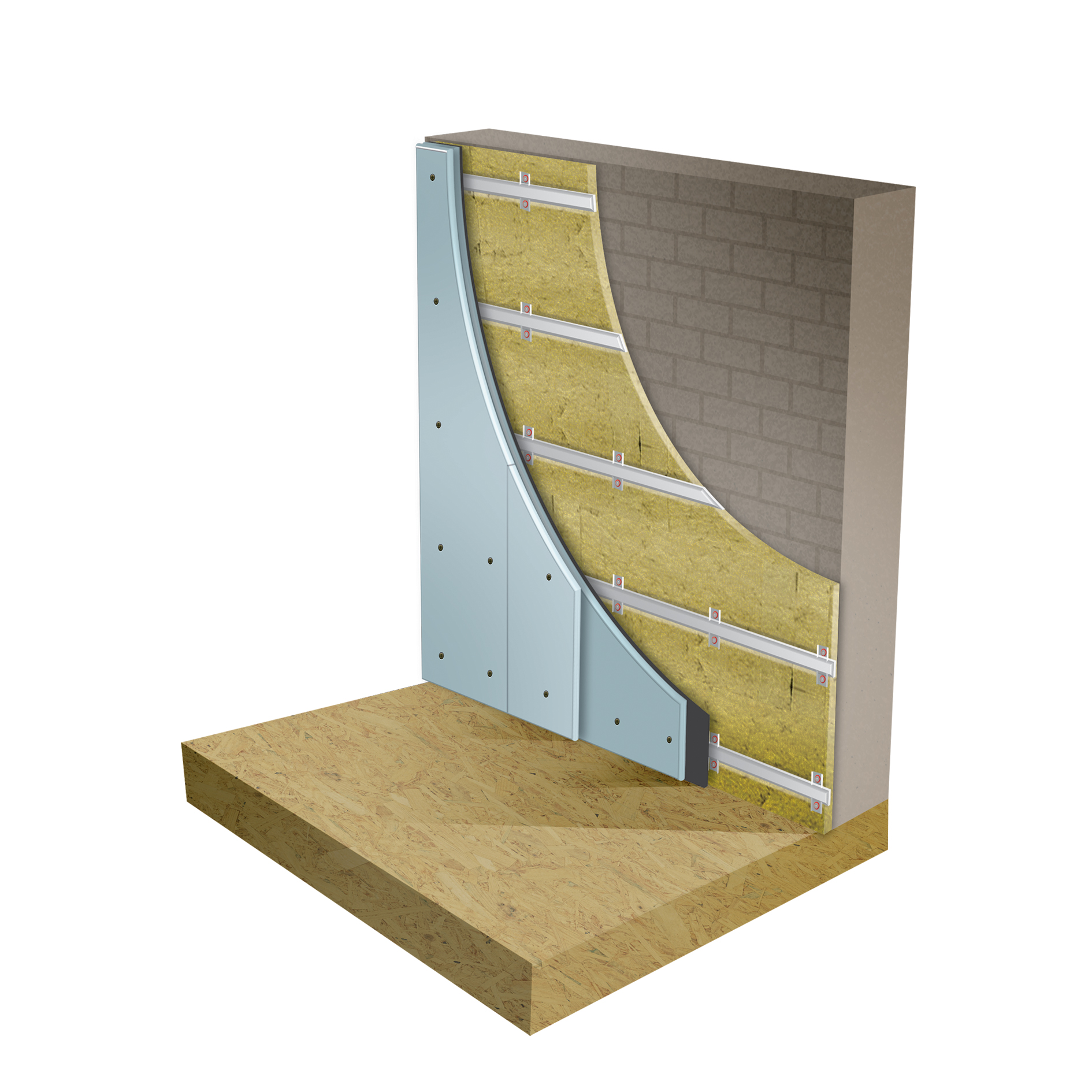

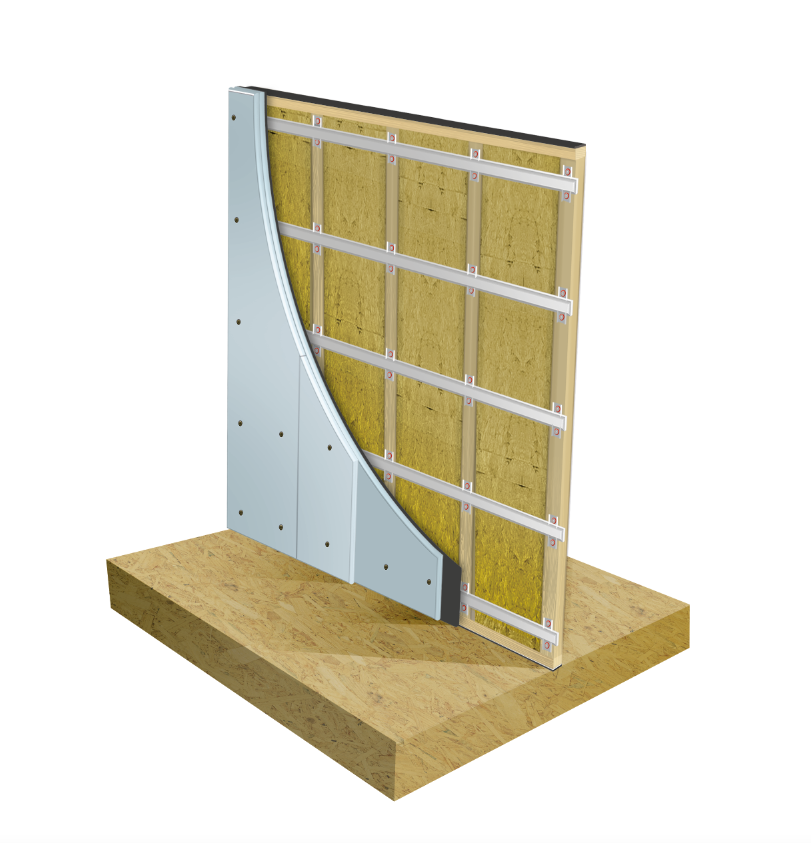

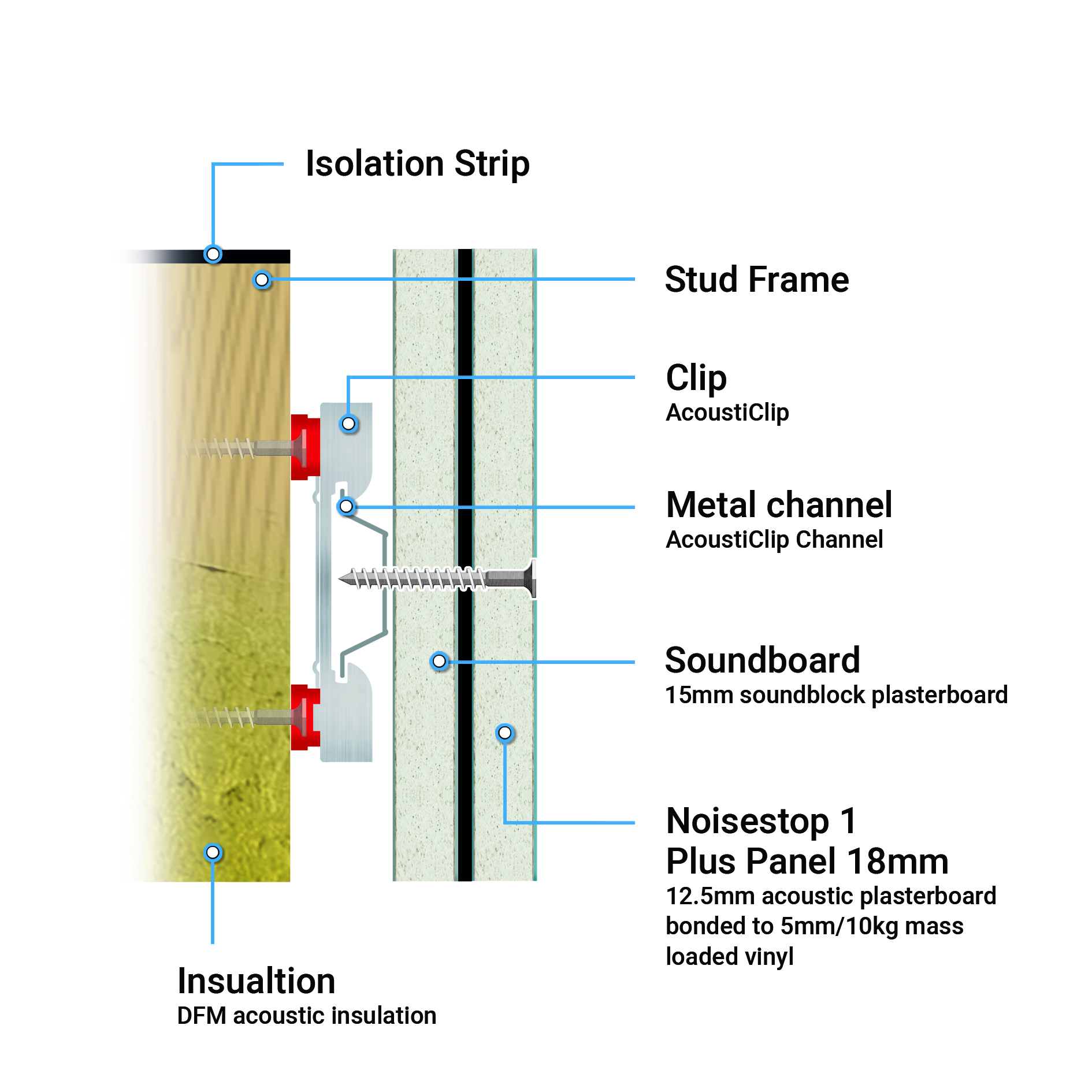

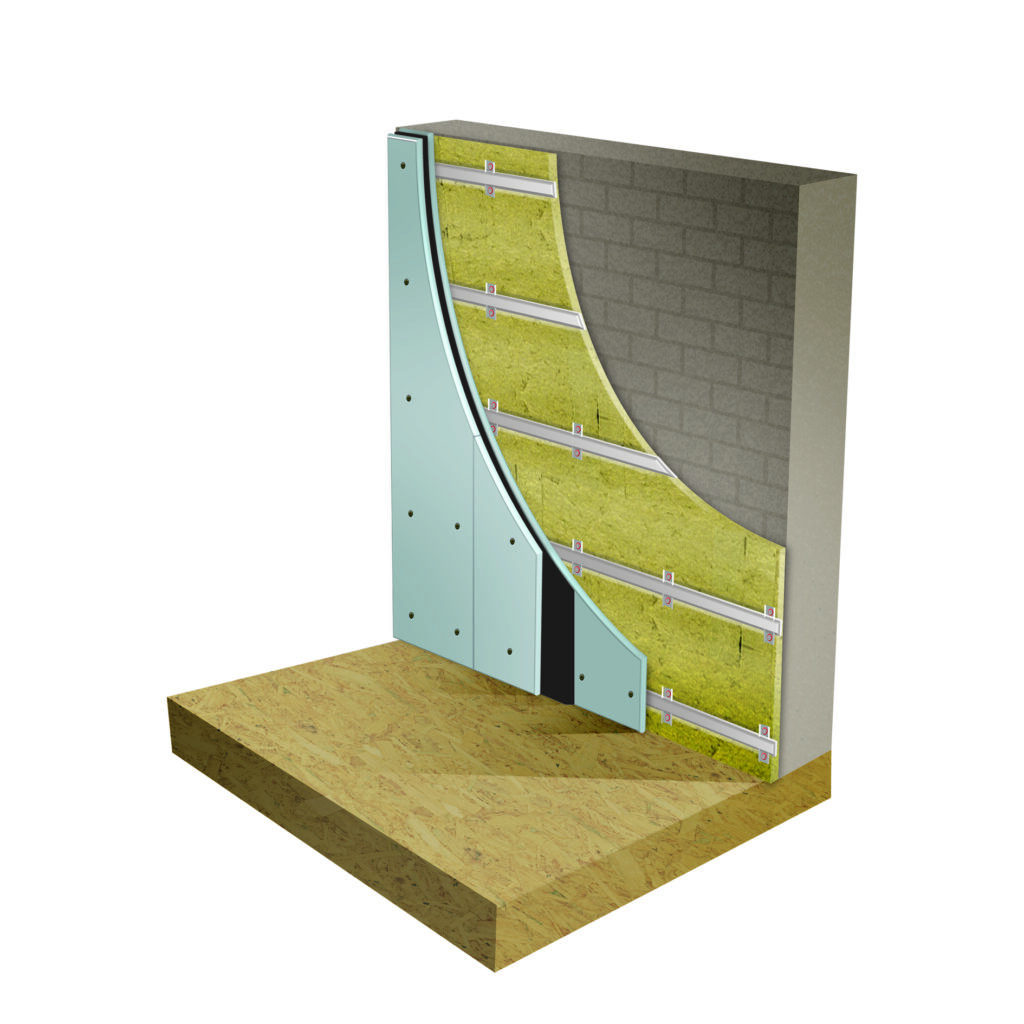

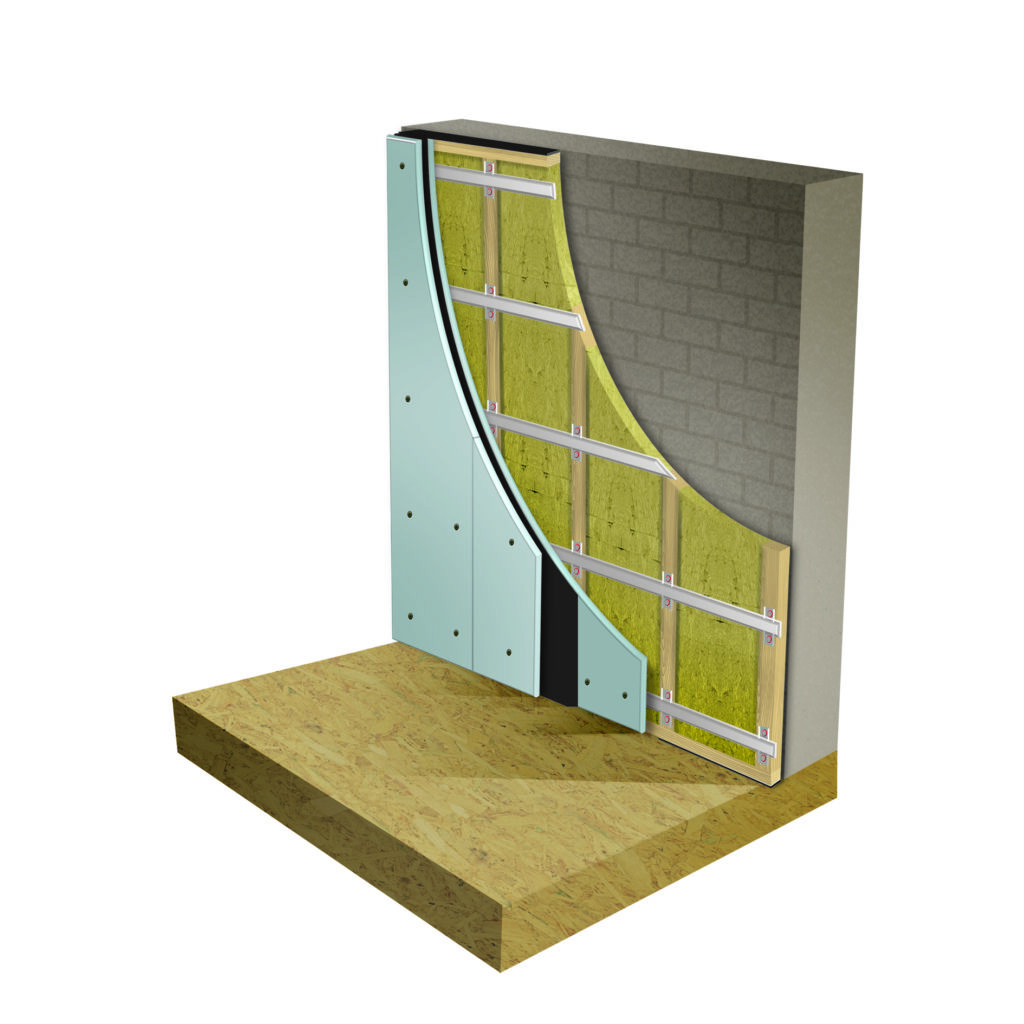

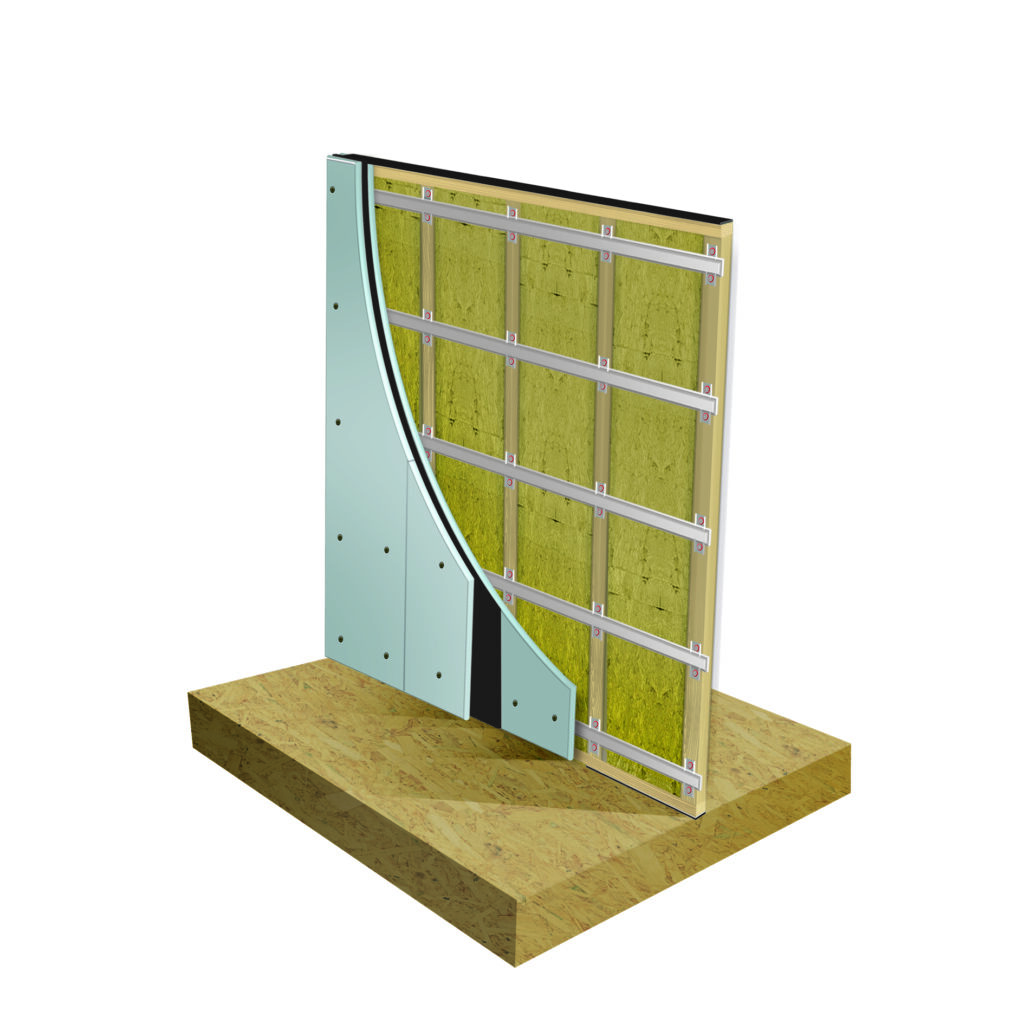

The AcoustiClip and AcoustiChannel is a high-performing solution designed to decouple walls and ceilings. Install the system directly to solid walls, stud frames, timber joists and concrete ceilings to significantly reduce sound transmission.

Fitting the AcoustiClip System to walls

- The spacing of the AcoustiClips along the AcoustiChannel is up to 1200mm.

- The maximum spacing between the AcoustiChannel is 600mm.

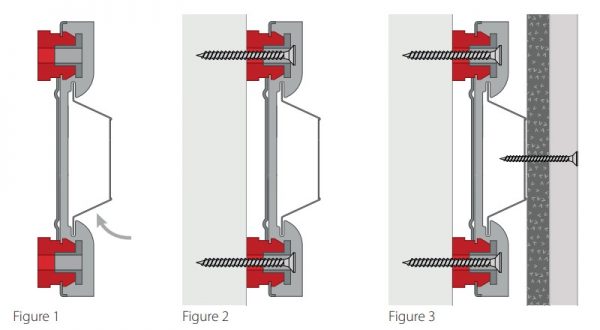

- The AcoustiClips can either be fixed to the wall before inserting the AcoustiChannel or inserted onto the AcoustiChannel before fixing to the wall.

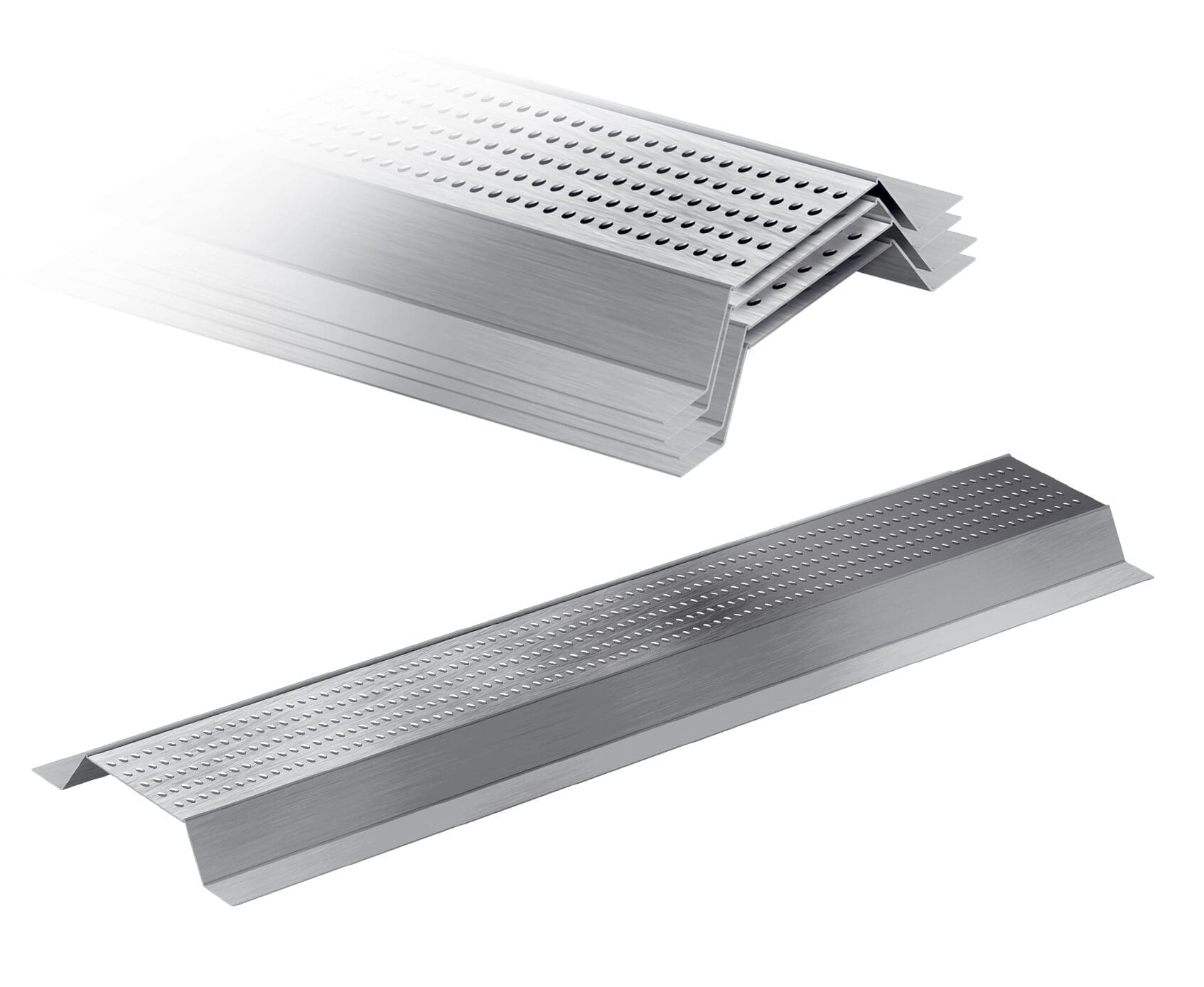

- The AcoustiChannel is easily fastened into the AcoustiClip by pinching the bridge of the channel and sliding the clips in place. (Figure 1)

- Fix the AcoustiClips to the wall using suitable screws for the background that the clips are being applied. Use a screw that is at least 60mm in length to secure. Take care not to crush the rubber impact inserts by over-torquing the screws. Use a mid-range setting on electrical drivers. (Figure 2)

- Overlap the AcoustiChannel by 100mm to join the AcoustiChannel lengths.

- Attach plasterboards to the Acoustichannel using drywall screws or suitable self-tapping screws for metal stud frames. (Figure 3)

Attaching AcoustiClip and AcoustiChannel to the wall

Fitting the AcoustiClip System to walls

- Ensure any stud frame is filled with acoustic insulation if you install the stud wall system. If you are installing a new stud frame, this can be isolated from the room using the isolation strips around the wall’s perimeter (not supplied with the system). For the direct to wall solution, apply the acoustic insulation between the AcoustiChannel.

- Install the acoustic plasterboard sheets by screwing them into the Acoustichannel. Use dry-wall screws or other suitable screws for self-drilling into a metal frame system of at least 10-15mm longer than the collective depth of the boarding.

- Increase the length of the screw for the second layer of boarding to account for the depth.

- When fitting the plasterboard sheets, ensure packers are used along the floor to isolate them from the floor; these can be left in place.

- Apply a bead of acoustic sealant along the edge of each panel as they are fitted. Leave a 2-3mm gap around the wall’s perimeter between the existing wall and ceiling; once the installation is complete, fill the gap with the acoustic sealant.

- Complete the installation by skimming the wall or filling the tapered edge plasterboard before decorating.

- Use acoustic putty pads inside any reinstated electrical outlets.

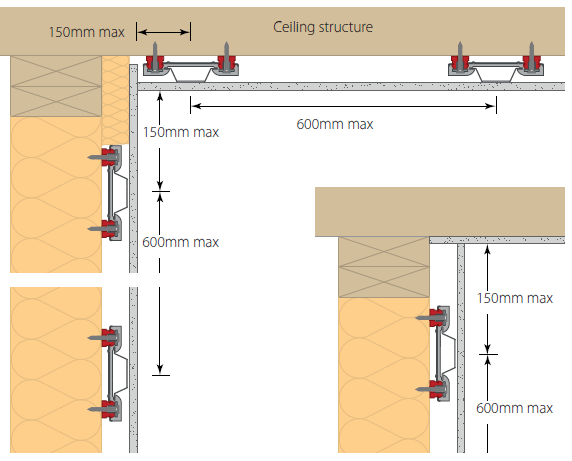

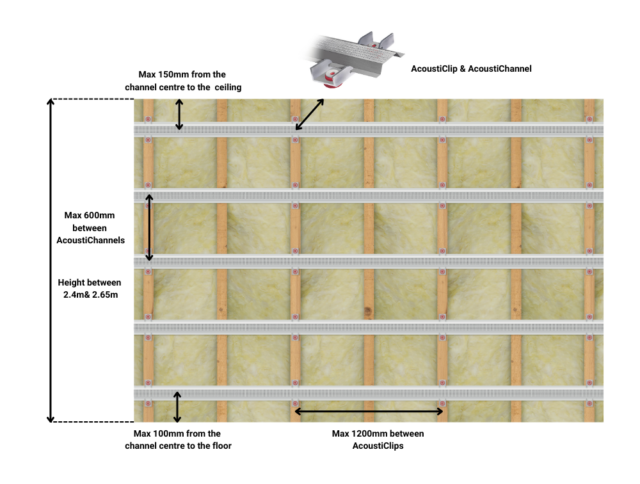

AcoustiClip and AcoustiChannel spacing for walls

- AcoustiClips spaced at 600mm centres for walls and ceilings.

- When fitting to walls, a 150mm gap can be left between the AcoustiChannel and the ceiling.

- When fitting to ceilings, a 150mm gap can be left between the AcoustiChannel and the walls.

- AcoustiClips are fitted at each end of the AcoustiChannel and a maximum of 1200mm between each clip.

- A maximum gap of 75mm can be left at the bottom of the wall from floor to channel, and a maximum gap of 150mm can be left at the top of the wall to the channel.

AcoustiClip Fitting Summary

- AcoustiClips can be fitted directly onto solid brick, concrete, and stud walls.

- AcoustiClips are fitted vertically to the wall at a maximum of 600mm centres and horizontally at a maximum of 1200mm centres. Install a clip at each end of the wall.

- A maximum gap of 75mm can be left from the floor to the centre of the first AcoustiChannel. A maximum gap of 150mm can be left between the ceiling and the top row of AcoustiChannel.

- When installing the system onto a stud frame, ensure the cavity is filled with the acoustic insulation supplied with the system.

- The acoustic insulation supplied with the Direct to Wall System is applied to the wall between the AcoustiCahnnel.

- When installing the first row of boards, place them on thin packers 2-3mm so they do not sit directly on the floor. Once the installation is complete, the acoustic sealant fills this gap.

- The soundproof panels are attached to the AcoustiChannel using drywall screws or self-tapping screws.

- Apply a bead of silicons between each board to ensure a complete acoustic seal.

- A gap of 2-3mm should be left around the wall’s perimeter, ensuring no part of the new wall touches the existing wall and ceiling. Use the acoustic sealant around the wall’s perimeter to fill the gap.

- To finish the wall, it can be plastered, or you can fill the tapered edge of the plasterboards before decoration.

- When reinstating electrical sockets, use Acoustic Putty Pads inside the back boxes to retain acoustic integrity.

Related Products

AcoustiClip Direct Party Wall System Soundproof Kit

£316.32 exc VAT.

AcoustiClip Solid Party Wall Stud System Soundproof Kit

£310.56 exc VAT.

AcoustiClip Stud Wall System Soundproof Kit

£310.56 exc VAT.

AcoustiClip - Sound Isolation Clip

£4.95 exc VAT.

AcoustiChannel 1800mm Metal Furring Channel

£4.45 exc VAT.

Wall Soundproofing

Make sure you are getting the right soundproofing for your needs. Understanding the most common types of noise and how to stop them will help you decide the right solution.

Different Types of Sound

- Airborne sounds – Conversation, TV noise and radios are examples of airborne sound. The best way to stop airborne sounds is to add mass/density to the walls or ceilings.

- Impact/vibration sounds – Footfall and moving furniture across a floor are examples of impact sounds. The best way to reduce these sounds is to create separation.

In summary, the best way to reduce airborne sounds is by increasing the mass of the area you would like to soundproof. Reducing impact/vibration sounds is achieved by creating separation within the structure.

Reducing Impact and Airborne Sounds

By following some of these steps, you will ensure you get the best level of soundproofing for your room.

- Mass/Density – Increasing the mass and density of the area you are soundproofing will block airborne sounds from transferring between rooms. You will increase the mass of walls and ceilings using materials such as soundproof panels or high-density acoustic insulation slabs.

- Separation – Incorporating separation within the structure will reduce vibration and impact sounds transferring between rooms. Achieve separation by building independent stud walls and ceilings. If you don’t have the space in the room, you can use acoustic clips and resilient channels to decouple the wall and ceiling.

- Absorption – Use materials that are going to absorb sounds. Acoustic insulation is suitable for sound absorption as it converts the sound waves into heat as it passes through the insulation. Dense mass-loaded barriers will also dampen and absorb sound.