Noisestop Acoustic Panel 22.5mm x 1200mm x 1200mm Soundproof Panel

£43.95 ex. VAT

In stock, ready to ship

Estimated Delivery: 3 - 5 Days

(3rd Nov - 5th Nov)

The Noisestop Acoustic Panel is the slimmest soundproofing solution for party walls. It effectively blocks neighbour noise without compromising your living space. Additionally, it enhances the sound insulation of stud walls, ensuring privacy in your home.

- Soundproofing: party walls, stud walls

- Noise type: Airborne noise (TV, radio, conversation lower-medium noise levels)

- Noise reduction: 49dB

- Size: 22.5mm x 1200mm x 1200mm (1.44sqm)

- Cost: £30.52sqm

- Installation: DIY friendly

- Finishing options: Plastering, tape and fill, paint or wallpaper

Noisestop Acoustic Panel is a slimline solution that provides noise reduction against household noise without compromising living space. At only 22.5mm thick, it is one of the slimmest soundproof boards available. Apply Noisestop Acoustic Panel directly onto brick party walls and internal stud walls to block airborne sounds.

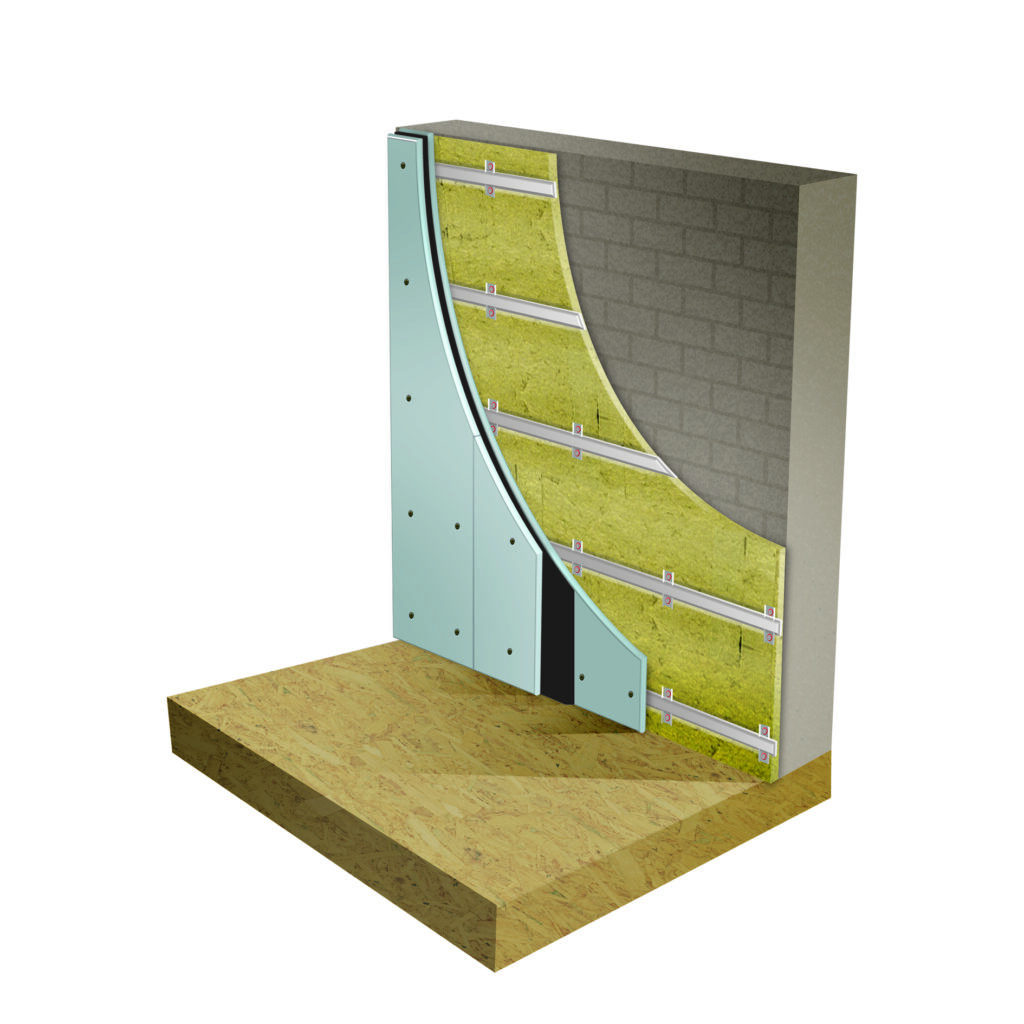

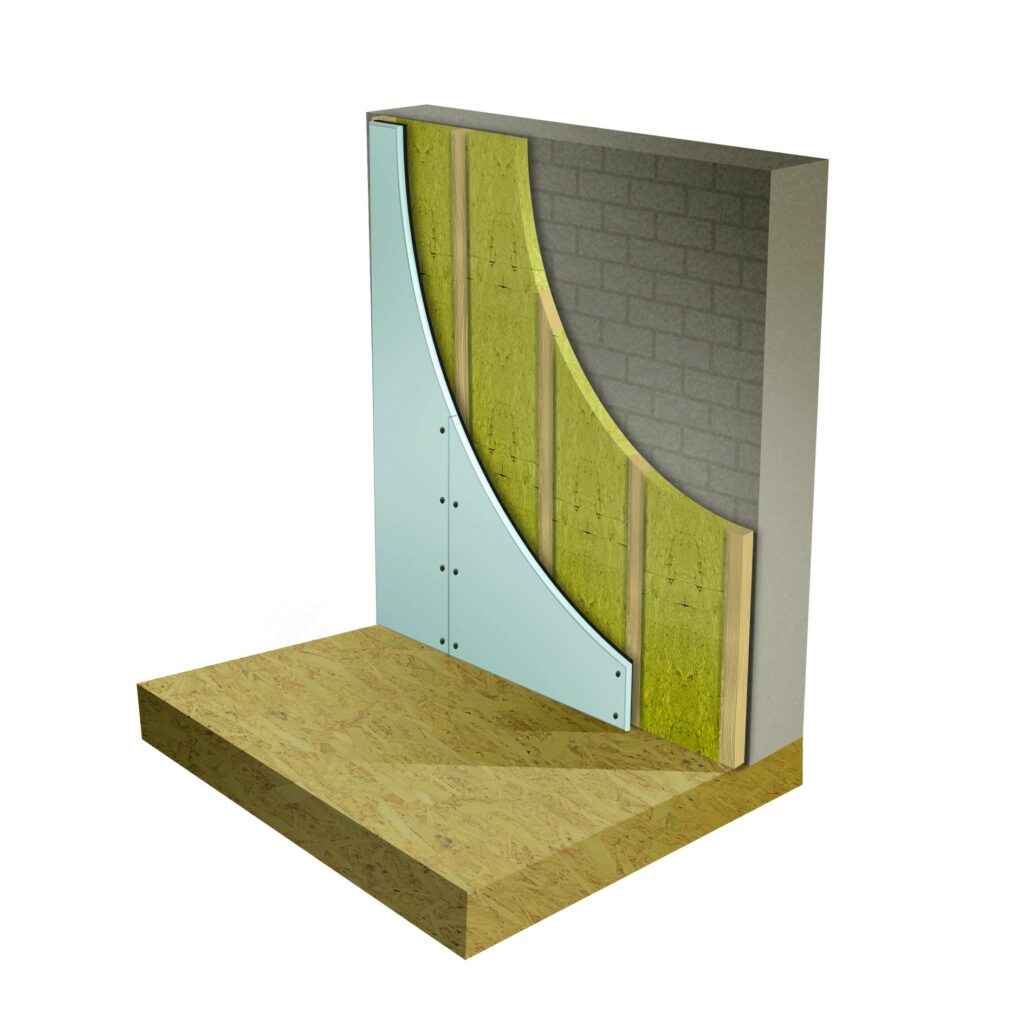

Noisestop Acoustic Panel offers soundproofing solutions for brick party walls, concrete blocks and stud walls. Noisestop Acoustic Panel, just 22.5mm thick, applied as a direct-to-wall soundproofing solution, effectively blocking up to 49dB on party walls. Part E is compliant and fire-rated for up to 30 minutes; it ensures airborne noise reduction without compromising living space. This slimline solution provides noise reduction against household noise without compromising living space.

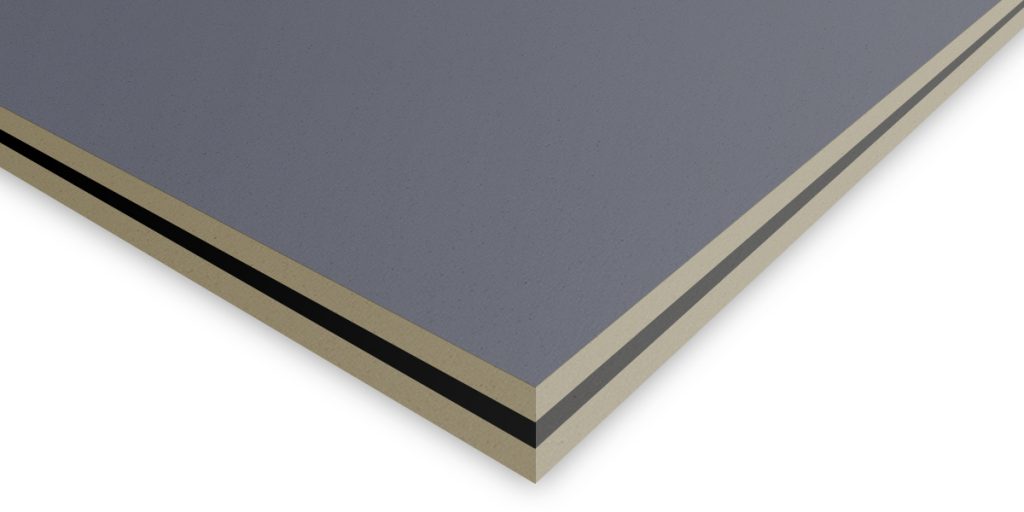

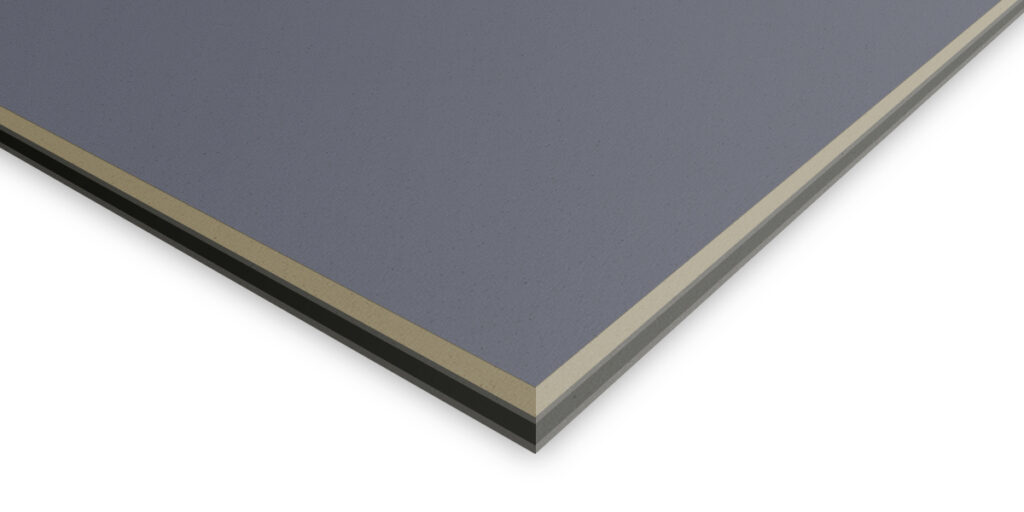

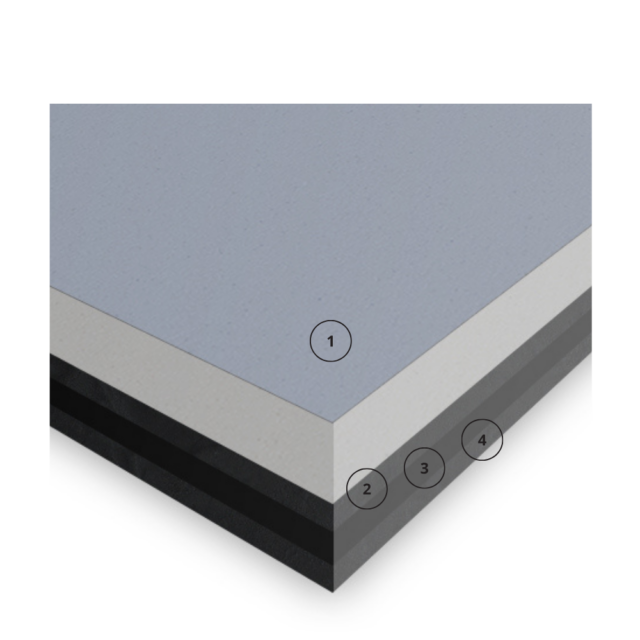

- Acoustic Plasterboard 12.5mm – Heavier than standard plasterboard, which adds density to the area. The plasterboard is finished in the same way as standard plasterboard.

- Mass-loaded vinyl 5kg/2.5mm – High mass barrier layer for sound absorption.

- Closed cell foam 5mm – Acoustic grade foam to dampen and absorb vibration sound.

- Mass-loaded vinyl 5kg/2.5mm – High mass barrier layer for sound absorption.

- Thickness: 22.5mm

- Size: 1200mm x 1200mm (1.44sqm)

- Weight: 29 kg

- Fire thirty minutes

Thermal Resistance R:

- Acoustic plasterboard 12.5 mm = 0.050 m2 K/W

- Closed Cell Foam: 0.23 m² K/W

- Mass-loaded vinyl 0.14 m² K/W

Thermal Conductivity λR:

- Acoustic plasterboard 0.25 W/mK to BS EN 12524:2000

- Closed Cell Foam: 0.039 W/mK

- Mass-loaded vinyl 0.037 W/mK

Reaction to Fire

- Acoustic plasterboard 12.5mm Euroclass A2-s1, d0

- Closed Cell Foam: FMVSS 302

- Mass-loaded vinyl 10kg EN 13501-1 B-s2,d0 (2)

Brick Wall

Untreated brick wall DnT,w

Single skin 100mm brick wall 38db

Treated brick wall DnT,w

Noisestop Acoustic Panel applied 49dB

Improvement DnT,w

Noise reduction with treatment 11dB

Stud Wall

Untreated stud wall DnT,w

Untreated 100mm stud wall with acoustic insulation and 12.5mm plasterboard on either side 36dB

Treated stud wall DnT,w

Noisestop Acoustic Panel applied to one side 48dB

Improvement DnT,w

Noise reduction with treatment 12dB

Note: Every 10 decibels(dB) reduction in noise level is roughly perceived as a halving of the perceived loudness. So, for instance, if you have a sound that measures 70dB and it decreases to 60dB, it would sound about half as loud to the human ear. Decibels explained.

NOTE: When the panel is installed, the plasterboard layer faces into the room, and the acoustic membrane on the back of the board goes onto the wall.

- Ensure the surface you are applying the panels is in good condition, make good any remedial work to the existing wall to ensure it is flat and secure before you attach the panels.

- Remove skirting boards and coving and extending electrical outlets; these can be reinstated once the work is complete.

- Begin the installation by installing the bottom row of boards. Leave a 2-3mm gap between the floor and the boards using 2-3mm packers or an equivalent to support the panels.

- Apply the Noisestop Acoustic Panel to the walls using Hammer Fixings or the Smart Tack Adhesive. We only advise using the adhesive on flat walls; approximately one tin will fix five panels. Fix the panels using nine hammer fixings per board if the wall is uneven or in poor condition. Screw the panels onto timber or metal studs with drywall screws.

- Use acoustic sealant between each panel as you put them together.

- Leave a 2-3mm gap around the wall’s perimeter to reduce flanking sound transmission, and apply an acoustic sealant to fill the gap once the installation is complete.

- Cut the panels using a hand saw or a circular saw.

- Skim plaster or tape and fill the tapered edges.

- Upon completion of the soundproofing, reinstate the skirting and coving.

- If you are reinstating electrical outlets, use acoustic putty pads inside recessed back boxes.

Due to the nature of most of the materials we supply, orders are typically delivered on pallets.

All orders will be wrapped, protected, and secured to the pallet to ensure they arrive in the best possible condition. Goods will be delivered as near to the property as possible. The drivers will not be able to carry orders into your property.

Deliveries are made between 8am and 6pm, Monday to Friday.

Once an order has been placed, you will be notified of the expected delivery date. Please ensure someone is available to sign for the delivery.

We charge a flat delivery rate of £60 plus VAT for palletised deliveries. We do not charge per pallet, no matter how many pallets are used to deliver your order.

Orders placed for items weighing less than 20kg will be sent via courier for £20 plus VAT.

We have a high stock level, so we typically deliver orders in approximately three working days.

If you want to speak to us regarding your delivery, please call 01423 339163.

Please check out our full delivery terms for more details.

Soundproof panels FAQS

Soundproof panels are specialised acoustic panels designed to reduce sound transmission between spaces. They are typically made of dense, sound-absorbing materials such as soundproof plasterboard, mass-loaded vinyl and acoustic foams, which help to block and absorb sound waves.

No. Soundproof panels significantly reduce sound transmission, but achieving higher levels of soundproofing requires combining various methods and materials (such as sound isolation clips, resilient channels and acoustic insulation). See our Soundproofing Systems for more information when higher levels of sound insulation are required.

Yes, many soundproof panels are designed for easy DIY installation. They are typically installed with screws or adhesives depending on the type of panel and the surface they are being applied. Products frequently used with soundproof panels include the following.

- Acoustic sealants – seal the edges and the perimeter of the wall to keep the area airtight.

- Hammer fixings – Secure sound panels to most solid walls using a hammer fixing. Other fixings, such as drywall screws, are used for different backgrounds, such as stud work or metal furring channels.

Most soundproof panels have an outer face of plasterboard, which allows for finishing, such as a plaster skim like a standard plasterboard. Our soundproofing boards have a tapered edge that enables them to be taped and filled as an alternative to plastering. Decorating straight onto the panel’s surface with paint or wallpaper is possible.

Once the soundproofing has been installed, the electrical outlets can be reinstated. To ensure acoustic integrity, we recommend using an acoustic putty pad inside the electrical back box.

You can attach things such as shelves and mirrors over soundproof panels. If the wall behind the panel is a solid wall, use a suitable fixing that connects to the wall behind the panel; if it’s a stud wall, use a suitable stud wall plug.

Alternative solutions

Alternative solutions that will offer different levels of soundproofing or another kind of installation method that might suit your requirements.

Got a question?

Send us a message, and we’ll respond as soon as possible. Alternatively, call 01423 339163 to speak with an adviser.