Soundproofing Floors FAQs

Soundproofing Floors FAQs – Everything you need to know about soundproofing floors

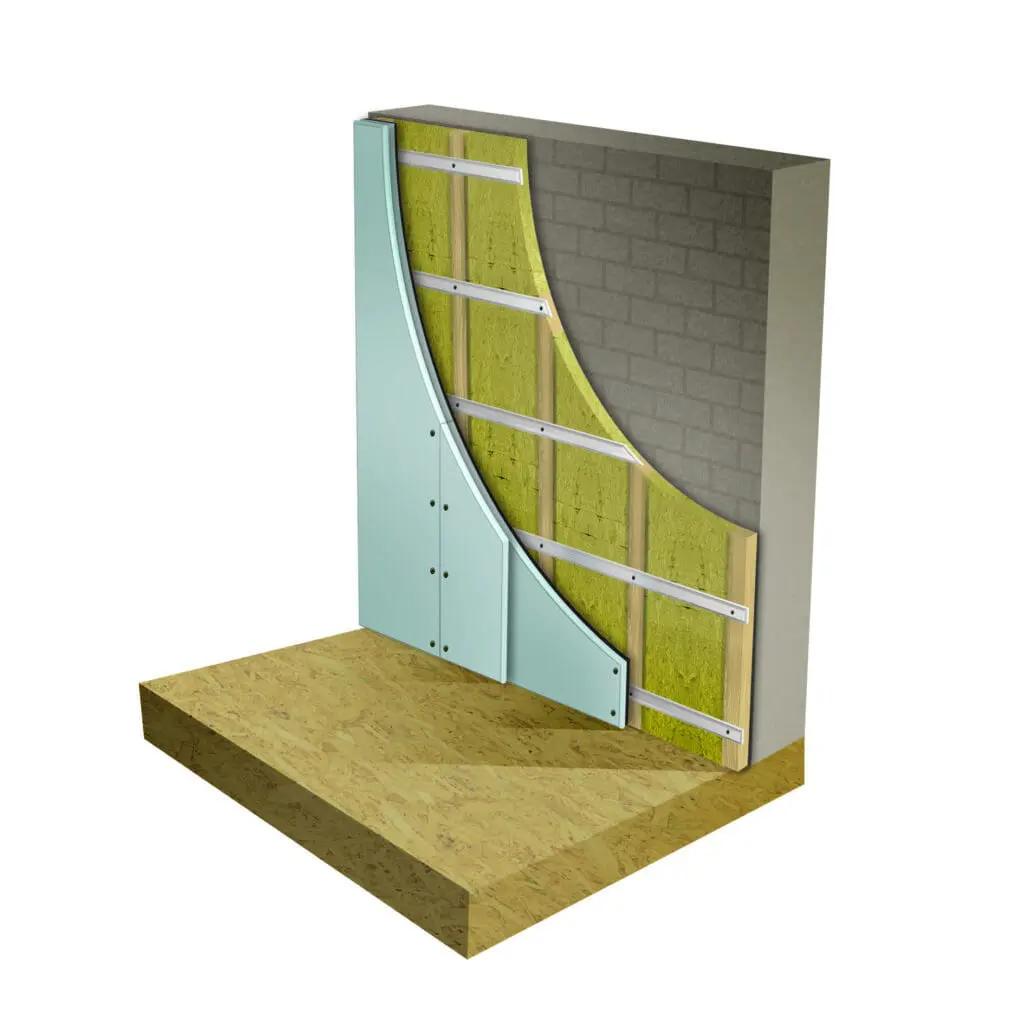

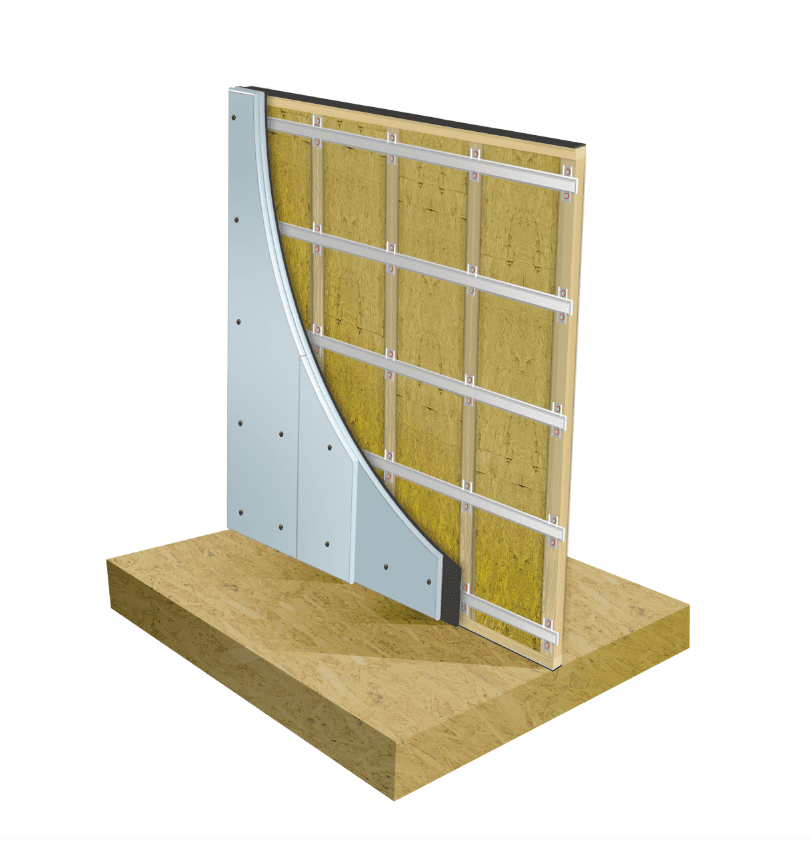

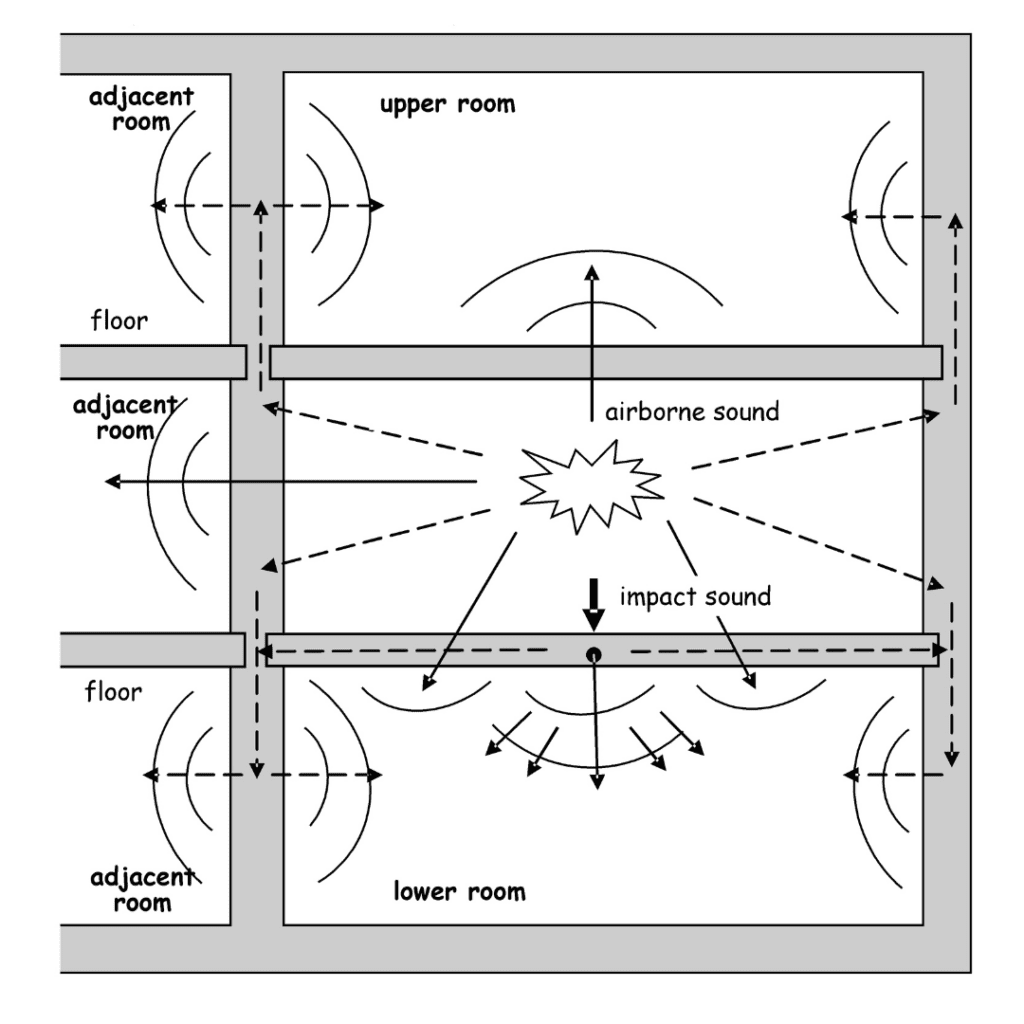

- Using products that add mass and density to the floor helps block airborne sound from passing through.

- You can improve a floor’s sound absorption by adding resilient layers and acoustic insulation in the floor cavities. Acoustic underlays also help absorb impact sounds, such as footsteps and movement.

- Combining different soundproofing products gives you the best results.

- Adding acoustic insulation in floor cavities stops resonant sound from getting louder.

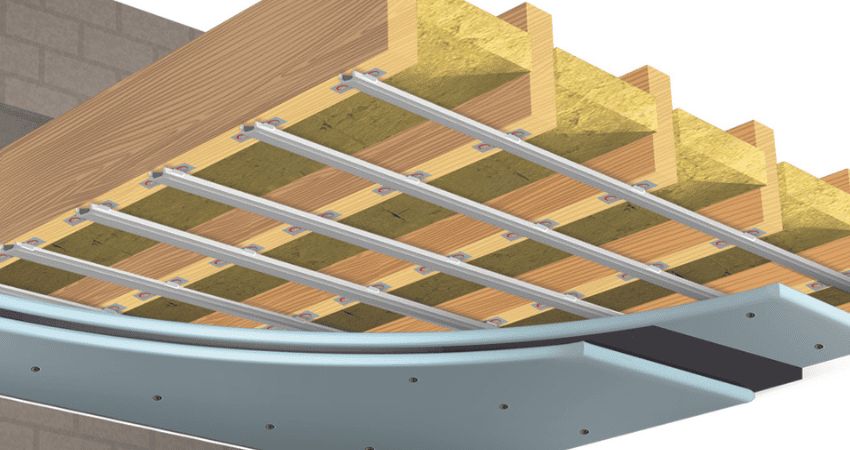

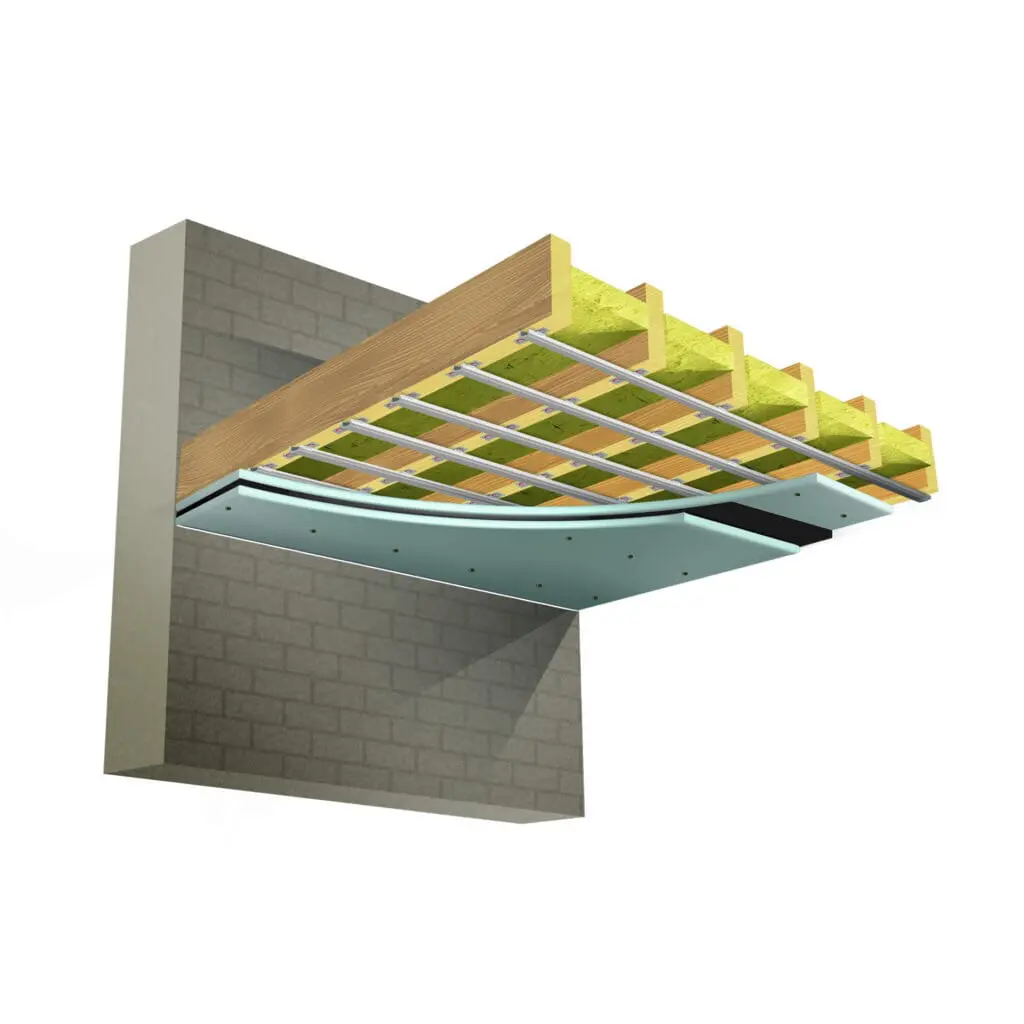

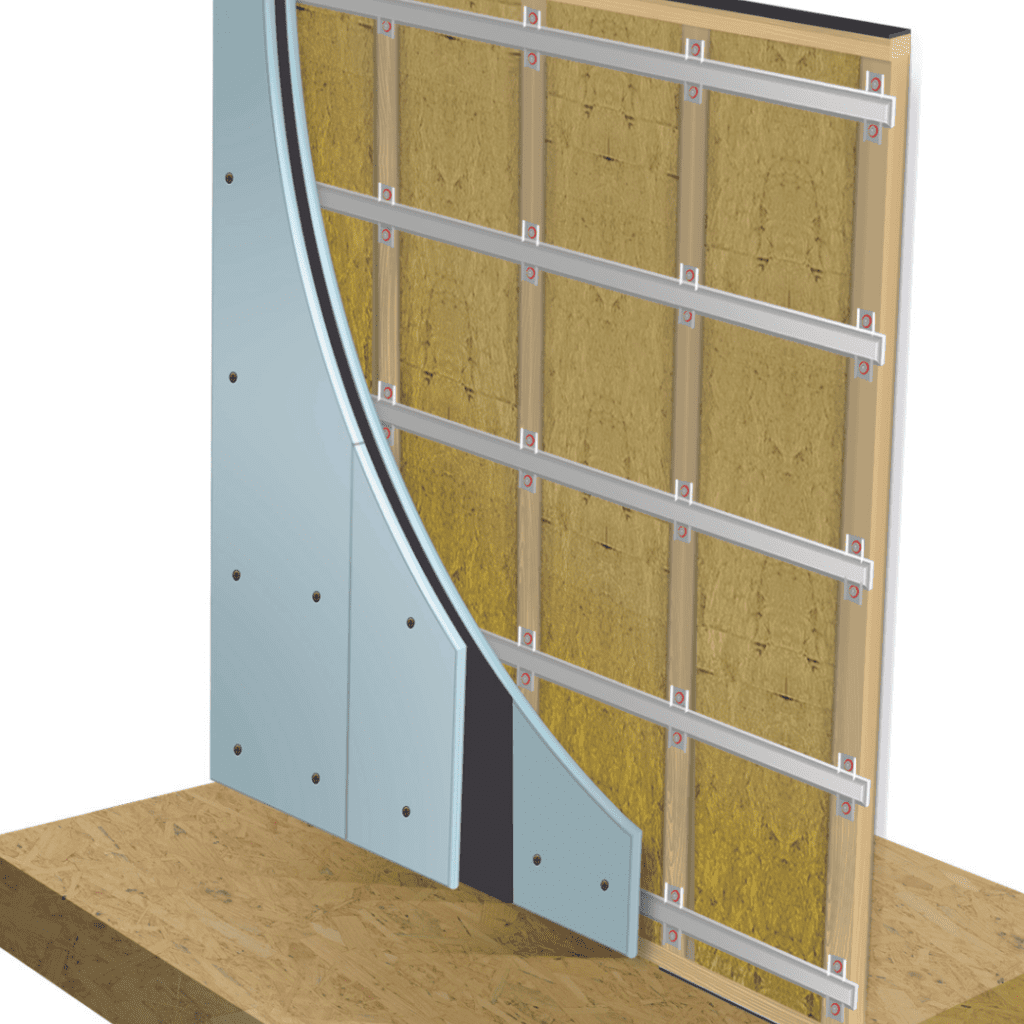

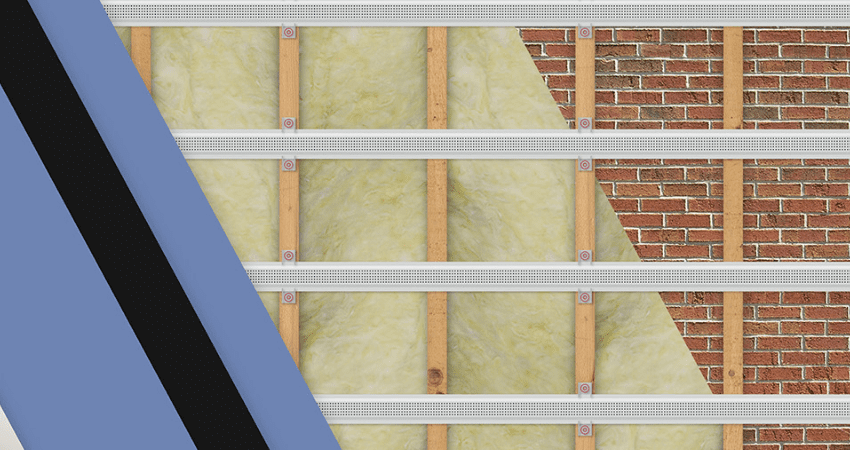

- Insulate the cavity between the floor and ceiling with acoustic insulation slabs. The best insulation for us is 100mm/60kg/m3 dense slabs. Filling ceiling voids will block sound from passing through the floor, and sound insulation in the cavities will prevent sound from transferring between floors.

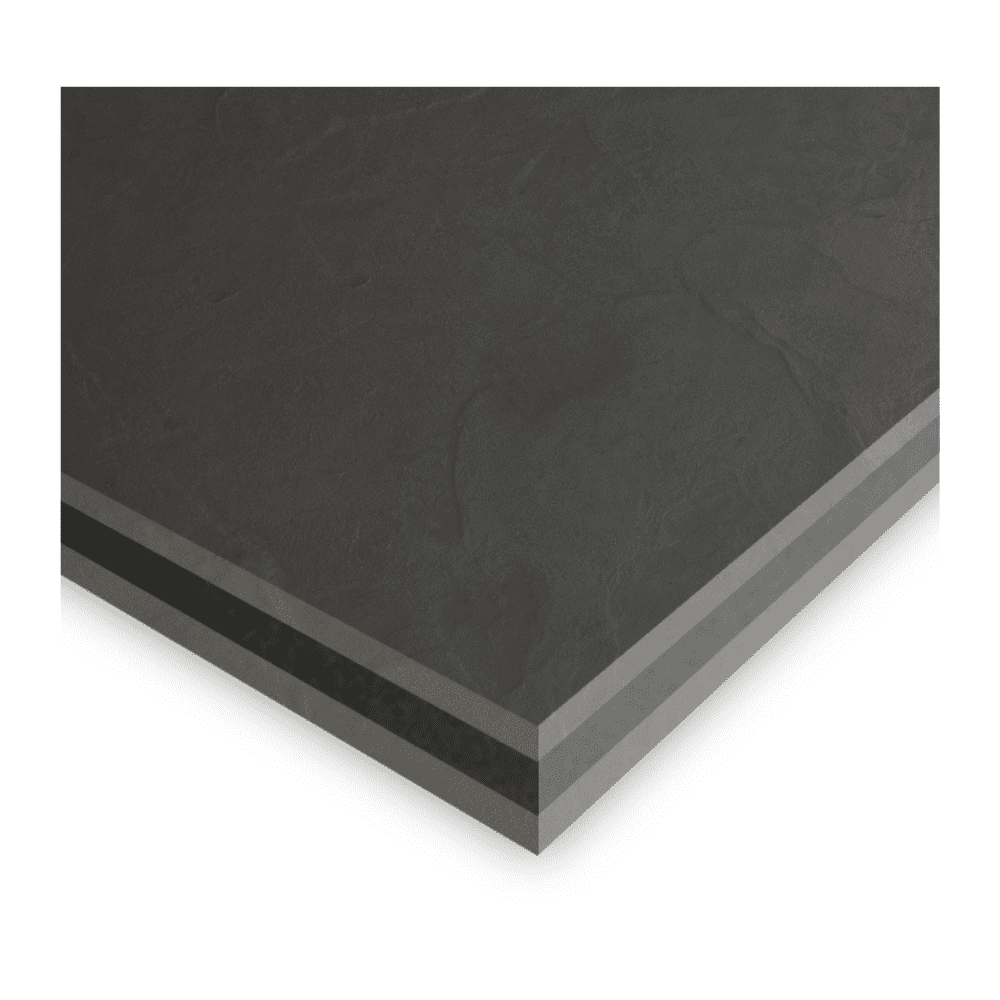

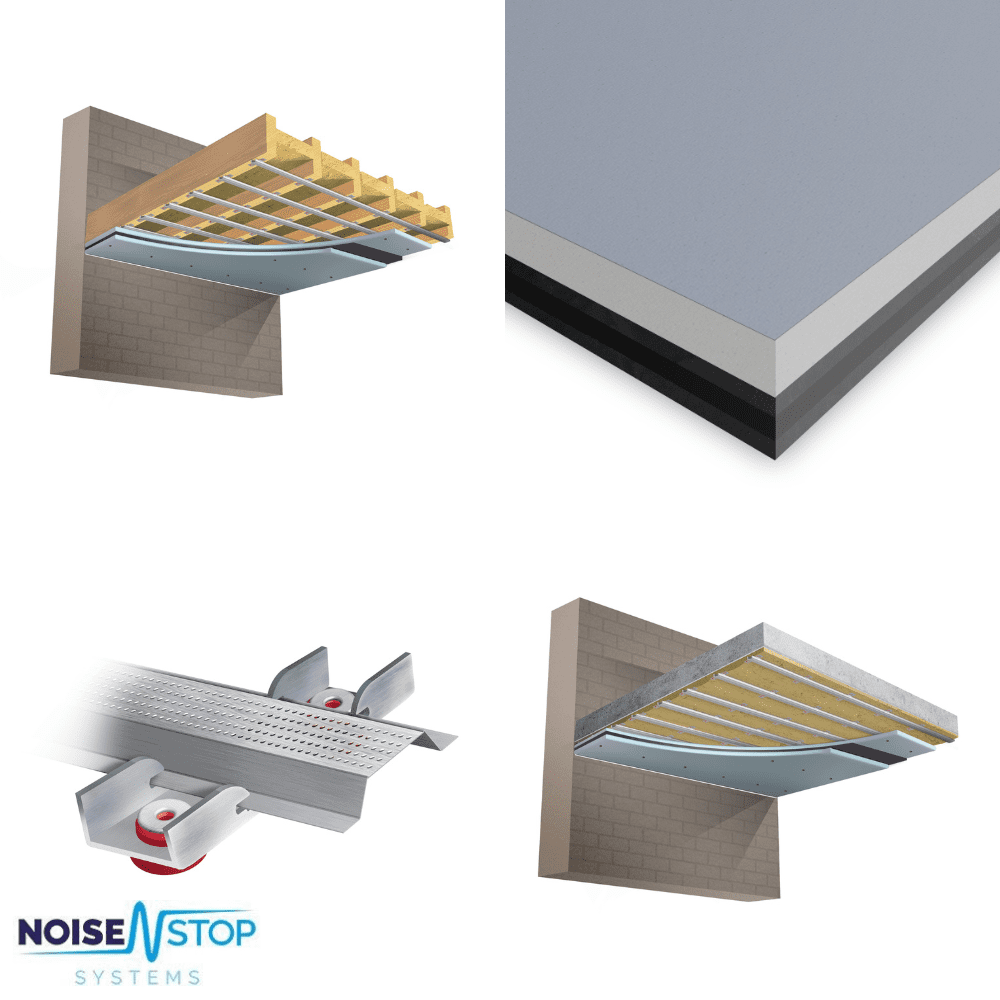

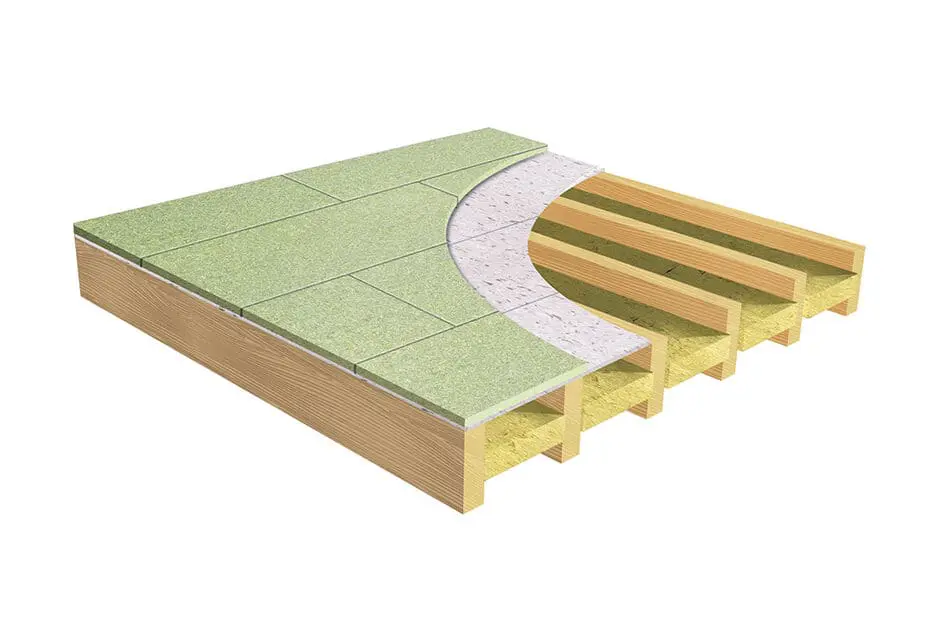

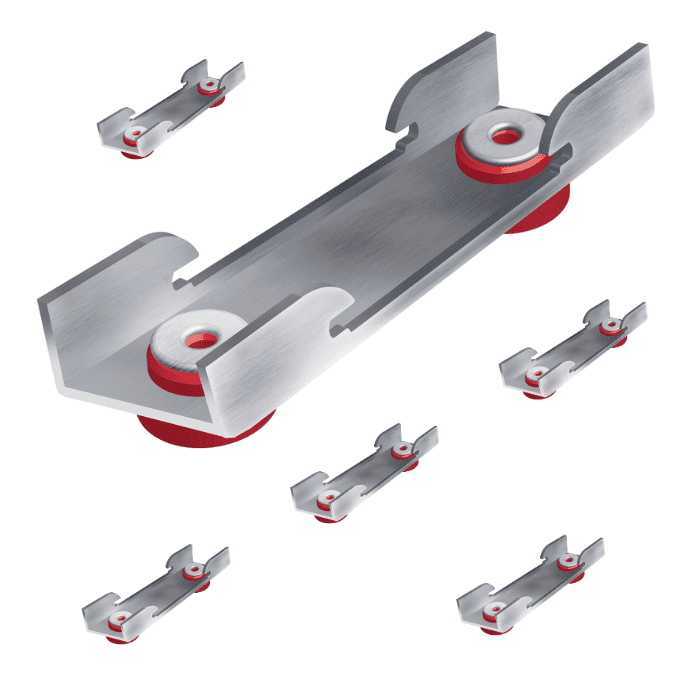

- Lay a resilient layer over the floorboards to prevent sound from the floor’s structure from entering the room. Acoustic underlay mats and floating floors are used to absorb impact sounds, such as footfall, as they pass through the floor. We will look at acoustic underlays and floating floors on this page and discuss which are suitable for each.

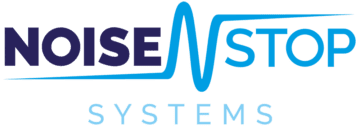

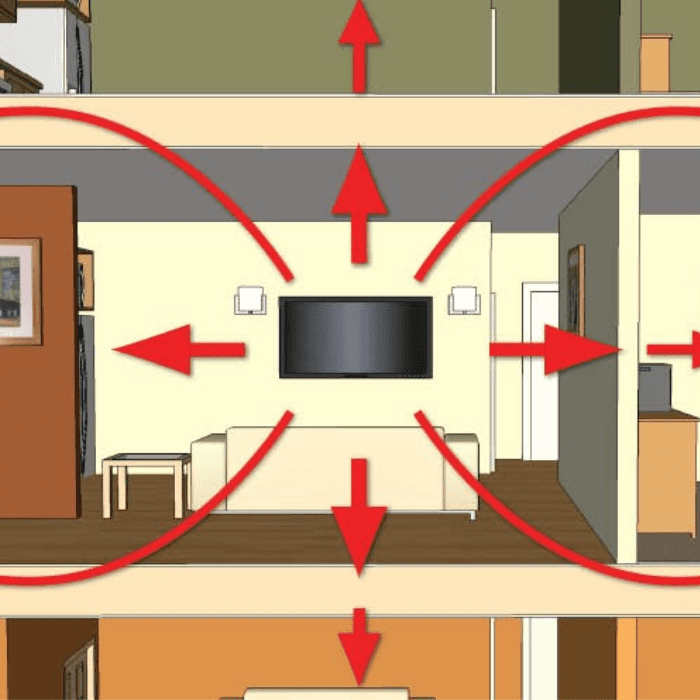

- Reduce flanking sound between floors and walls using an isolation tape or flanking band around the perimeter of the room to decouple the soundproofing floor from the walls. In doing this, you reduce potential sound transfer passing from the floor and into the walls, which could then transfer noise up and down the walls.

- Isolating floor joists from the floorboards is another method of decoupling the floor to reduce the transmission of impact and vibration sounds through the floor.

Many flooring solutions can be installed by the homeowner. Alternatively, carpet fitters will normally lay soundproofing products when they fit carpets. Some structural flooring systems, like floating floors, can be installed by local tradespeople. Overall, fitting flooring products is easier than some of the more complex wall and ceiling solutions.

Hopefully, you have found answers to your floor soundproofing questions. Take a look at our floor soundproofing products page and begin your floor soundproofing journey. If you do need more help, send us an enquiry or call 01423 339163 and speak with one of our helpful team members.

Soundproofing categories

Some popular floor soundproofing products

12mm Soundproof Acoustic Underlay 1.2m x 1.2m

£31.95 exc VAT.

F7 Plus 15mm Soundproof Underlay 1.2m x 1.2m

£41.95 exc VAT.

Noisedeck 19 - T&G Overlay Floating Floorboard 1.2m x 0.6m

£15.95 exc VAT.

Noisedeck 28 - T&G Direct to Joist & Overlay Floating Floorboard 2.4m x 0.6m

£29.2 exc VAT.

Noisedeck 32 - T&G Direct to Joist Floating Floorboard 2.4m x 0.6m

£32.95 exc VAT.

Acoustic Insulation Slabs - Soundproof Insulation

£43 exc VAT.

Perimeter Isolation Tape 25m x 100mm x 5mm

£12.3 exc VAT.

Perimeter Edging Gripper Rod Strips 9mm x 1200mm x 25mm

£5.65 exc VAT.

Soundproofing posts

Categories

45 articles

Soundproofing Floors FAQs

How to Soundproof a Party Wall

How to Soundproof a Ceiling

How To Soundproof Walls

How To Soundproof a Stud Wall

Best Way to Sound Insulate a Wall

Best Sound Insulation For Walls

How to Soundproof a Room for a Home Cinema

Meeting Part E Building Regulations When Converting a Property into Separate Dwellings

What is the difference between airborne and impact noise?

What are the Best Soundproof Underlays?

Wall Sound Insulation

Best Soundproofing Products 2025

Soundproofing Materials for Walls

Understanding Sound Insulation

Guide To Soundproofing Your Home

Soundproofing Materials for Ceilings

Part E Acoustic Solution for Timber Joist Separating Floors: Using Noisedeck 32, Insulation, and Soundbreaker Bars

AcoustiClip Acoustic Wall Systems

Acoustic Sound Insulation Guide

Soundproof Insulation vs. Acoustic Insulation: Understanding the Difference

Flanking Noise

How To Pass Part E Building Regulations