The best way to soundproof stud walls

Minimise noise transmission through internal timber frame walls using the best acoustic insulation for Soundproofing stud walls. Constructing a soundproof stud wall means choosing the best sound insulation products to improve the wall’s mass and density and decouple the wall’s structure. One of the cheapest ways to soundproof stud walls is to use soundproofing insulation manufactured to improve the mass and sound absorption capabilities of timber stud walls. This specialised insulation effectively dampens sound waves, creating a quieter environment. However, product combinations will ensure the best soundproofing results for stud walls. By selecting soundproofing panels, sound insulation slabs and decoupling isolation clips, you will maximise the soundproofing of the stud wall. Ensure the highest level of sound insulation for your stud walls by choosing the AcoustiClip Stud Wall System, which comprises all the soundproofing you need to create quieter spaces in your home.

The best soundproofing solution for stud walls

Use the AcoustiClip Stud Wall System to soundproof timber frame stud walls

A complete soundproofing solution for stud walls to restore quiet in your home. The system supplies all the soundproof materials required to insulate stud walls.

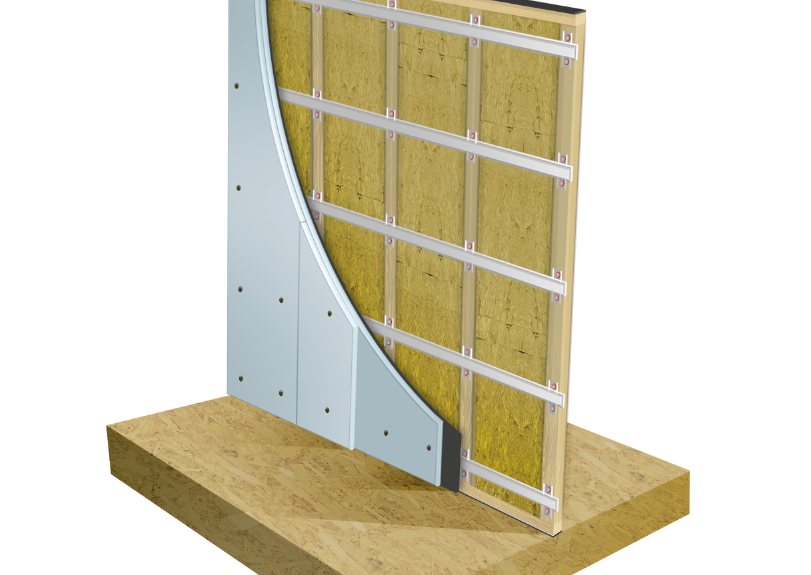

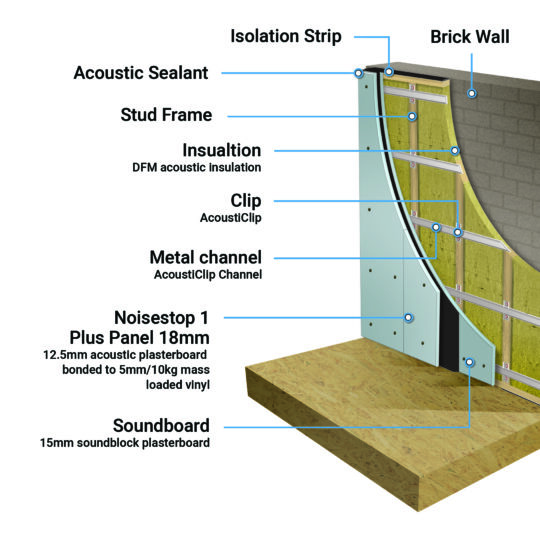

The AcoustiClip Stud Wall System is applied to one side of the stud frame. Once the existing plasterboard has been removed, the sound insulation slabs fill between the stud frame. The AcoustiClips and AcoustiChannel are fixed to the face of the studs. The soundboard plasterboard and specialist Noisestop 1 Plus Panel soundproof panel are affixed to the AcoustiChannel to form the acoustic wall.

- Add mass/density to your stud walls with the high-density acoustic insulation slabs and soundproof panels.

- Decouple the stud frame from the soundboards with the AcoustiClip and AcoustiChannel system affixed to the timber stud frame.

AcoustiClip Stud Wall Soundproofing System

Soundproofing materials for stud walls

Use these materials to soundproof a new or existing stud wall to stop airborne and vibration noise. Soundproofing stud walls involves adding materials that absorb, block, or dampen the sound transmission.

Acoustic insulation to soundproof stud walls

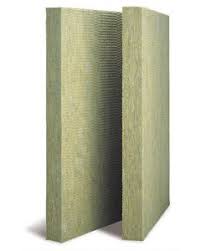

To increase the density of the wall and its ability to absorb sounds, acoustic insulation slabs should be placed between the timber stud frame. It is recommended that 60kg density is used for internal stud walls. The thickness can vary depending on the stud frame’s depth, and filling the cavity is unnecessary. The sound insulation slabs act as an absorber for the sound to prevent sound from amplifying in the studs.

Decouple the stud frame to reduce sound transfer through the wall

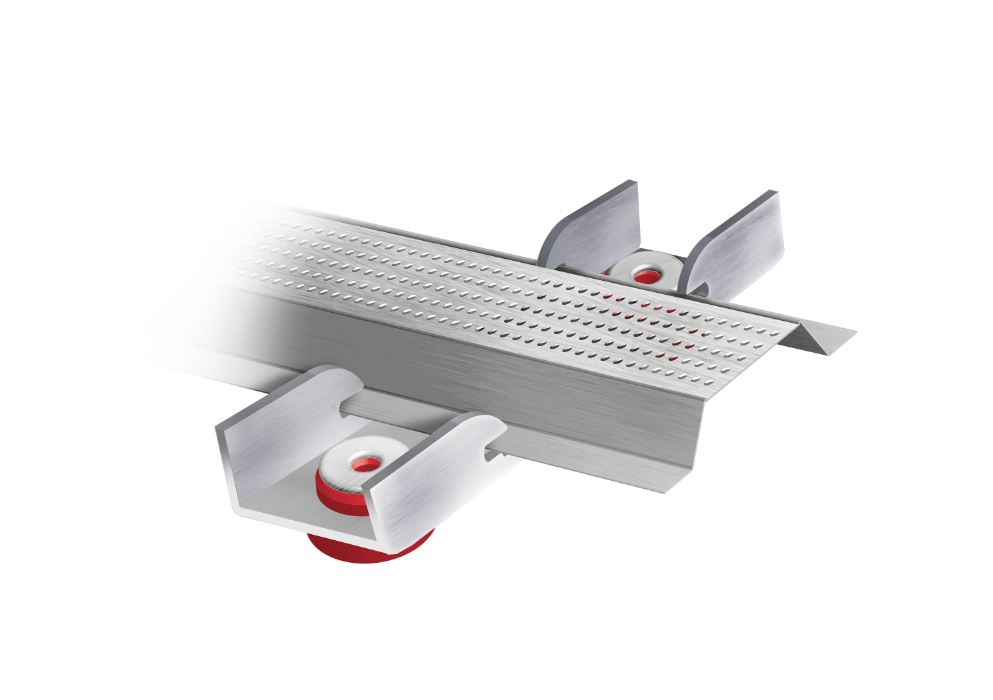

One of the most effective methods of soundproofing a wall is to enhance the walls ability to absorb vibration. Use a sound isolation clip to reduce vibration sounds from transferring through the walls. The AcoustiClip is an effective sound isolation clip that absorbs the vibration that carries the sound through the wall’s structure when applied to stud and party walls. Using the AcoustiClip within your wall soundproofing system will ensure the best level of soundproofing.

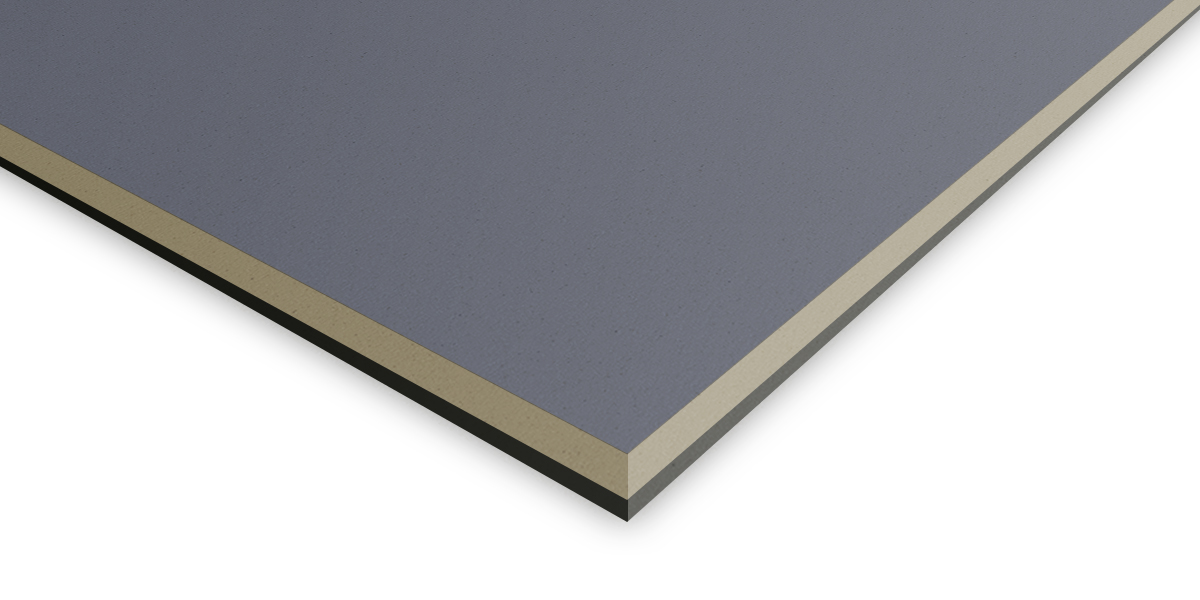

Add soundproof panels to your stud wall to improve the soundproofing

Finish your stud wall soundproofing with soundproof panels designed to increase the wall’s density. Improving the wall mass will block airborne sound transfer between the rooms. Applying soundproof boards over the existing plasterboard can increase the sound insulation of stud walls. Reduce low-level airborne sounds through stud walls with the Noisestop Silent Panel affixed over the existing plasterboard. Optimum soundproofing will be achieved using product combinations, as mentioned earlier, and for this, we recommend the Noisestop 1 Plus Panel as part of the soundproof system. Combining acoustic plasterboard and mass-loaded vinyl, which is pre-bonded to the plasterboard, makes the Noisestop 1 Plus Panel the best board to use with sound isolation clips and acoustic insulation when sound insulating a stud wall.

Insulation for stud wall soundproofing

DFM acoustic insulation slabs are an essential soundproofing material to increase the airborne sound insulation performance of stud walls, floors and ceilings. Because of its mass, density and sound absorption properties, acoustic insulation is used in soundproof systems inside ceiling cavities, stud walls and floor joists. Available in various thicknesses and densities, we recommend using the 60kg slabs for their acoustic performance. Acoustic insulation between the stud frames blocks and absorbs airborne sounds that transfer through untreated stud walls between rooms. Improving the mass and sound absorption is essential when you are sound insulating stud walls.

AcoustiClip – Sound Isolation Clip

The AcoustiClip reduces vibration sounds through walls and ceilings. AcoustiClip is a high performing sound isolation clip used to decouple walls and ceilings. Applying sound isolation clips to the stud frame will create an acoustic false wall. The AcoustiClip sound isolation clips attach to the stud frame and absorb the vibrations that transfer into the plasterboard. Use this decoupling clip as part of your separating wall or ceiling solution for superior levels of noise control. The AcoustiClip is featured in most of our wall and ceiling soundproofing systems as it reduces vibration and impact sound by isolating walls and ceilings. Combine the AcoustiClip with acoustic insulation and soundproof plasterboards, and you will ensure the best levels of noise control.

Noisestop 1 Plus Panel

Noisestop 1 Plus Panel is a high-mass, dense acoustic soundproof panel that will insulate ceilings and walls acoustically. It is designed to block the transmission of sound effectively. Noisestop 1+ Panel is instrumental in creating robust ceilings and wall linings. A premium, slim, high-mass acoustic board suitable for ceilings and walls. Outperforming standard ‘soundproof’ plasterboards, its versatility in installation makes it an ideal standout choice. This versatile panel combines mass and sound absorption in all our soundproofing wall and ceiling systems. Comprising a 10kg mass loaded vinyl membrane pre-bonded to a 12.5mm acoustic plasterboard eliminates the need for separate soundproof membranes. It significantly bolsters the sound insulation performance of walls and ceilings within soundproof systems.

Soundproof Plasterboard 15mm

Reduce noise transmission in your home with this high-density Acoustic Plasterboard 15mm. Soundproof plasterboards are denser than standard boards, so they will reduce more noise coming through stud walls. This acoustic plasterboard makes a fantastic soundproofing alternative for your home or workspace with a greater density than standard plasterboard. Once installed, you’ll notice a reduction in noise transmission through your walls and ceilings, especially when combined with other soundproofing solutions.

Isolation Strips

Isolate stud wall frames from the building’s structure or over floor joists to isolate the floorboards. Isolation Strips decouple surfaces, reducing sound transfer by absorbing vibration. They are supplied in 10-metre rolls with a self-adhesive (s/a) back. Noisestop isolation strips are quick and easy to install. Available in three widths: 50mm, 75mm and 100mm. Just choose the isolation strip that suits your wall or joist width. The self-adhesive backing will bond to the most common substrates.

Acoustic Sealant

AC50 acoustic sealant is a high-strength, permanently flexible acoustic sealant and adhesive. Acoustic sealants are specially formulated to seal the edges and around the perimeter of plasterboard walls and ceilings. One standard sealant tube will be enough to seal approximately five soundproofing panels at 1200mm x 1200mm. It’s available to buy in a standard 380ml or large 900ml size (you will require the large applicators to dispense the 900ml tubes).

Silent Panel

Noisestop Silent Panel, the highest performing direct wall soundproof solution, effectively block unwanted neighbour noise without sacrificing valuable living space. This 30mm thick soundproofing wall panel directly reduces noise transmission through walls, significantly reducing up to 52dB in audible airborne sounds. Specifically designed for timber stud, brick, and concrete block walls, the Noisestop Silent Panel is the top choice in our direct-to-wall soundproofing range, effectively combating clearly audible conversations and TV noise. Directly fixing to existing walls makes installation hassle free, ensuring minimal disruption for homeowners.

Stud wall soundproofing solutions

Stud walls are the most common construction method in homes to separate rooms, and these stud wall solutions will effectively block high noise levels. Stud walls can also be used to insulate party walls against noisy neighbours or to create a room within a room when a high level of noise control is required for studios and home cinemas.

Noisestop Systems provides a range of DIY stud wall soundproofing systems that combine all the necessary acoustic products.

Popular stud wall soundproofing systems

-

AcoustiClip Stud Wall System Soundproof Kit

£310.56 – £1,033.01 ex. VAT

-

AcoustiClip Solid Wall Stud System Soundproof Kit

£310.56 – £1,033.01 ex. VAT

-

Noisestop Silent Panel 30mm x 1200mm x 1200mm

£59.95 ex. VAT

Stud wall soundproofing conclusion

Soundproofing stud walls can greatly enhance the peace and privacy within a space. By implementing effective techniques such as using soundproofing materials, insulation, and proper construction methods, it’s possible to reduce the transmission of sound between rooms significantly. Whether for a home, office, or any other environment, soundproofing stud walls can make a notable difference in creating a more peaceful and comfortable atmosphere.

Related Products

-

AcoustiClip Stud Wall System Soundproof Kit

From £ 310.56 ex. VAT -

AcoustiClip Solid Wall Stud System Soundproof Kit

From £ 310.56 ex. VAT -

Noisestop Silent Panel 30mm x 1200mm x 1200mm

From £ 59.95 ex. VAT